Table of Contents

近期文章

What Does Professional PCBA Service Include?

If you manage engineering, hardware, or procurement, you need a partner who can take designs from validation to stable mass production. That is what a professional pcba service delivers. It covers NPI and DFM, supply chain, manufacturing, testing and quality, box build, project management, and cost and lead time control. The goal is simple: ship products that meet quality, reliability, and compliance requirements, without surprises.

End-to-End PCBA Capabilities at a Glance (Design to Delivery)

- NPI/DFM/DFT/DFA: Early engineering for manufacturability, testability, and assembly.

- BOM and component sourcing: Global supply, alternates, and lifecycle control.

- SMT/DIP (THT) assembly: From 01005 to BGA/QFN on stable lines.

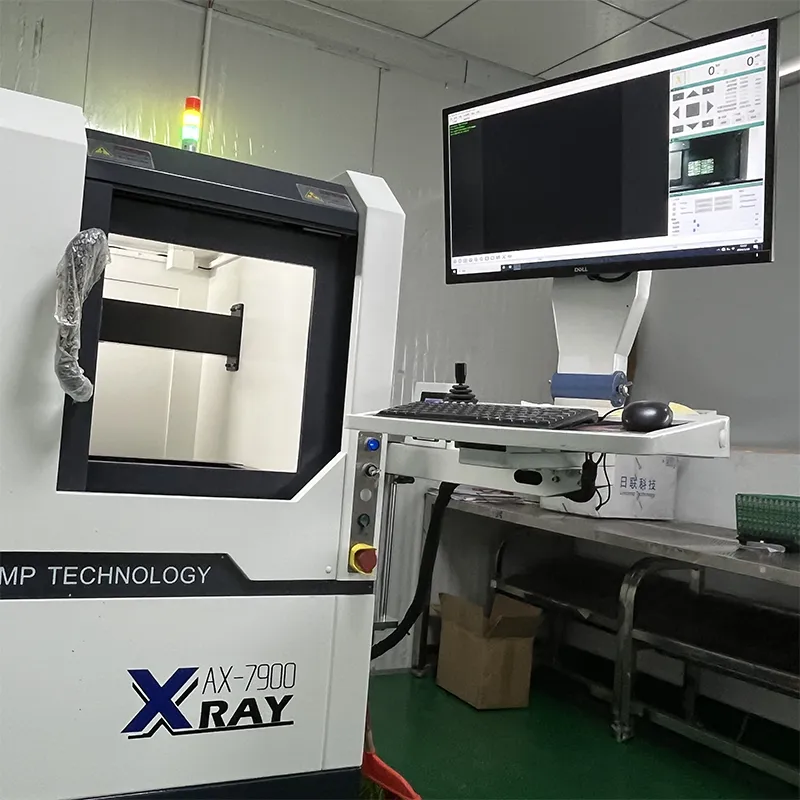

- Test (ICT/FCT/boundary scan/flying probe/X-Ray): From incoming to final inspection.

- Conformal coating and potting: Environmental and reliability protection.

- Box build: Cables, enclosures, firmware programming, and system integration.

- Packaging and shipment: Custom packaging and compliance labels.

- Quality and traceability: Lot and serial trace from end to end.

- After-sales and service: Rework, replacement, and long-term technical support.

NPI and Early Engineering: Move from Design to Volume

One-and-Done Handoff Checklist (Reduce Back-and-Forth)

- BOM with alternates, AVL for key parts, and package parameters

- Gerber/ODB++, netlist, panel and rails

- Centroid (pick-and-place) file, assembly and silkscreen drawings, stack-up notes

- Test specs (ICT/FCT), test point list, and coverage targets

- Programming files, serial number rules, and labeling schema

- IPC assembly class (IPC-A-610 Class 2/3) and special process notes (lead-free/lead)

DFM/DFT/DFA Review Essentials (Based on Real Line Constraints)

- DFM: Pad and solder mask openings, stencil thickness and apertures, placement clearance, BGA and fine-pitch solderability, cleanability, and thermal design

- DFT: Test access on key nets, probe reach, boundary-scan chain, fixture feasibility, and coverage goals

- DFA: Part orientation consistency, barcode and trace label placement, balanced operations, and fixturing

- Standards referenced: IPC-A-610, J-STD-001, J-STD-020/033 (MSL and reflow profiles)

Prototype and Pilot Builds (Reduce Production Risk)

- Prototype/EVT: Small batches for fast functional and solderability checks

- DVT pilots: Larger sample size to validate process windows and test coverage

- PVT (production validation): Run at production takt to lock parameters and yield goals

- Line outputs: FAI, process records, issue list, and corrective closure

Materials and Supply Chain Management

Sourcing and Incoming Materials (Balance Quality, Cost, and Lead Time)

- Global sourcing and price negotiations; prioritize long-lead and risk parts

- IQC checks: ID, appearance, key parameters, and documentation completeness

- Anti-counterfeit and traceability: COC, lot trace, supplier audits

- ESD and MSL control: Storage/bake/reflow per JEDEC

- Small-batch trade-offs: Unit price is higher, but validation risk is lower

BOM Optimization and Alternate Strategy (Mitigate Shortages and Control Cost)

- Alternates and multi-source strategies (package compatibility, electrical equivalency, risk assessment)

- Lifecycle monitoring (active/EOL/NRND) and PCN tracking

- Buffers for critical parts and rolling forecasts to reduce line stoppage

Quality and Traceability (Receiving to Shipping)

- IQC sampling plans, supplier scorecards, and annual audits

- Lot and serial trace (part number/lot/date code)

- RoHS/REACH, halogen-free, and UL material declarations

- Learn more: BOM procurement and alternates (/bom-procurement), Quality and compliance system (/quality)

Procurement Models: Turnkey vs. Consigned

Model | Who buys parts | Best for | Notes |

Turnkey | EMS provider | Speed, cost control, single ownership | Strongest for shortage mitigation |

Partial consigned | Split | Key IP/strategic parts held by customer | Aligns control and flexibility |

Full consigned | Customer | Legacy supply chains | Higher handling and coordination |

Manufacturing Capabilities: SMT, THT, and Secondary Processes

SMT Assembly Scope

- Component range: 01005, QFN, BGA/uBGA, fine-pitch connectors, double-sided

- SPI/AOI coverage; BGA and QFN bottom joints verified by X-Ray sampling

- Closed-loop reflow control with on-line thermocouple recording

- Leaded/lead-free options; double reflow, dispensing, selective solder processes

THT and Soldering

- Wave and selective wave soldering for mixed-density and heat-sensitive zones

- Manual soldering per IPC J-STD-001; critical joints verified under magnification or microscope

Secondary Operations and Rework

- BGA rework: remove/replace, reball, X-Ray confirmation

- Custom fixtures: assembly jigs, coating masks, test nests

- Dispensing/potting, TIM application, heatsink install with torque control

- Connector crimp and pull-force testing

Surface Protection and Special Processes

- Conformal coating (acrylic/silicone/urethane) per IPC-CC-830

- Potting (epoxy/urethane/silicone) with durability, flame, and serviceability trade-offs

- Coating thickness checks, coverage inspection, and masking in critical zones

Test and Quality Control (Coverage with Clear Data)

In-Process and Final Testing

- SPI: Solder paste quality gate

- AOI: Polarity, shift, missing parts, and solder condition

- X-Ray: BGA/QFN hidden joints and plated-through-hole fill sampling

- ICT (bed-of-nails): Component values and shorts/opens; best for mid to high volume

- FCT: Powered functional tests under realistic conditions

- Flying probe: No fixture; ideal for prototypes and high-mix, low-volume

- Boundary scan (IEEE 1149.1/1149.6): Complex interconnects and logic checks

- Burn-in and stress tests: High temp soak/cycle and power cycles

- Coverage and defects closed-loop: 8D, fishbone, and recurrence prevention

Test Method Selection Guide

Method | Needs Fixture | Best Stage | Typical Use |

SPI/AOI | No | All | Process control and early catch |

X-Ray | No | Proto–Mass | Hidden joints and hole fill |

Flying probe | No | Proto/Pilot | Low-NRE, many variants |

ICT | Yes | Pilot–Mass | Fast structural coverage |

FCT | Often | Pilot–Mass | System-level functional checks |

Boundary scan | Minimal | Proto–Mass | Digital interconnect/logic test |

Quality System and Compliance

- IPC-A-610 Class 2/3, J-STD-001, UL recognized materials

- ISO 9001; apply ISO 13485 for medical and IATF 16949 for automotive programs as needed

- RoHS/REACH environmental compliance and material statements

- ESD system per ANSI/ESD S20.20; process SPC with Cp/Cpk tracking

Traceability and Data Visibility

arcode/QR serials with unit-level IDs

- MES records: process, equipment, operator, lots, and test data

- FAI, patrol checks, and lot reports; yield and top defect charts

- Learn more: Functional and reliability testing (/functional-test)

Box Build and Shipment

- Cable and wire harness, panel and enclosure assembly, torque standards

- Firmware programming, serial rules, calibration, and factory parameters

- Packaging, labels, and compliance marks (CE/FCC); manuals and accessory kits

- Outgoing inspection and COA/COC as required; sampling and retains

- Explore box build capability (/box-build)

Project Management and Communication

- Single point of contact (PM): requirements, work orders, and cross-team coordination

- Milestones: NPI review, prototype, pilot, mass build cadence, SOP freeze

- Weekly reports/visual boards: schedule, material risks, and defect closure

- Risk alerts: shortages/alternates, process bottlenecks, fixture and test gaps

- Change control (ECO/ECN): assessment, validation, version and material cut-in control

- Document security and NDA: access control, data retention, and audit trails

Cost Structure and Lead Time

Cost Drivers

- Materials: components, bare PCBs, fixtures, and consumables

- Process complexity: density, double-sided/mixed tech, special materials

- Test: fixture and software development, coverage requirements

- Yield and rework: process windows and defect control

- Quantity breaks: scale effects and scheduling efficiency

- Packaging and logistics: custom packs, international shipping, insurance

Cost-Down and Efficiency Tips

- DFM: stencil and aperture tuning, via design, part commonality

- Alternates: equivalent parameters and multi-source plans

- Panelization and rails: better material use and line efficiency

- Fixture reuse and modularity: shorter development and lower NRE

- Test optimization: layered strategy (ICT + FCT) for faster fault isolation

Lead Time Tiers and Expedites

- Prototypes: typically 5–10 working days when key parts are available; full-turnkey often 1–2 weeks

- Small-batch/pilot: 2–4 weeks including fixture and test prep

- Mass production: rolling schedules with SLA-based commits; expedite lanes for urgent programs

Why Choose a Professional PCBA Partner vs. a Small Shop

- Quality system: certified and process-controlled vs. experience-only management

- Traceability depth: lot/serial tracking vs. manual logs

- Test capability: automated, measurable coverage vs. basic functional spot checks

- Delivery stability: SLA planning vs. variable lead times

- Engineering support: NPI team and continuous improvement vs. ad-hoc effort

- Compliance risk: passes customer and regulatory audits vs. missing documentation

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact us

to Begin your Bessiness