PCBAYCT—A LEADING PCB Assembly MANUFACTURER IN CHINA

- 8 Production Lines to Ensure On-time Delivery

- Have specialized in customized PCBA projects for over 15 years

YCT—Reliable, Rapid, Professional PCB Assembly Manufacturer from China

Your reliable PCB assembly manufacturer

Can help you to improve your production effectively

YCT—One-Stop PCB Assembly Service Factory

YCT is a PCB assembly factory. We provide one-stop full-service PCBA R&D, design, solution, SMT patch, DIP plug-in, post-soldering, testing, and assembly to provide customers with efficient and high-quality PCBA business. At the same time, we can also provide customers with PCB board production, Bom order matching, electronic components procurement and other services.

YCT is your partner to support your electronic design and win the market for your products, better, faster, and at a lower cost.

PCBA OEM & ODM

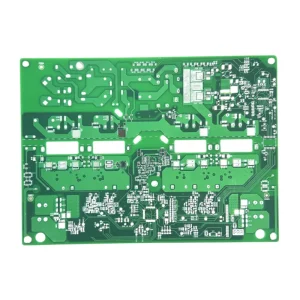

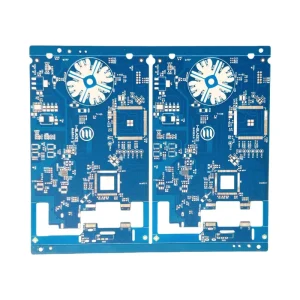

PCB

YCT—The Leading Choice in Professional PCB Assembly Industry

With over ten years of experience in the electronics industry, YCT specializes in providing high-quality PCB assembly services. Our professional team is proficient in SMT processing, PCBA manufacturing, and circuit board welding. Equipped with advanced production equipment and strictly adhering to the ISO9001 and IATF16949 quality management systems, we ensure superior product quality. Backed by a comprehensive supply chain and exceptional customer service, we are committed to becoming your most trusted partner in the PCB assembly field

Technology

YCT professional electronic engineers and BOM engineers have more than ten years of experience in the electronic industry, they are specializing in SMT processing, SMT patch processing, PCBA processing, circuit board welding, etc..

Equipment

YCT is equipped with DESEN automatic printing machine, Panasonic NPM high-speed chip mounter, JUKI chip mounter, JT wave furnace, ten temperature zone reflow oven, QUICK robot, YATAI terminal machine, and other first-class production equipment.

Quality

YCT as an SMT patch factory, has passed the ISO9001 and IATF16949 system authoritative certification and implemented the quality system production, management, and quality concepts of PCBA, SMT, SMT patch and wiring harness.

Supply Chains

YCT integrates upstream and downstream resources, establishes a complete supply chain system, and establishes strategic partnerships with many brand component manufacturers to provide delivery and quality assurance for foundry materials and electronic assembly.

Services

The project-based organizational structure composed of business, engineering and quality, guided by the project-specific responsibility system, provides quick response, timely feedback, decision-making and other services for pre-sales and after-sales services.

Response

YCT is a SMT chip processing factory. The company adopts a flat organizational structure and establishes a compact and capable service team. In response to customer concerns, questions and requirements, production progress and status, etc., with the ability to respond quickly and efficiently.

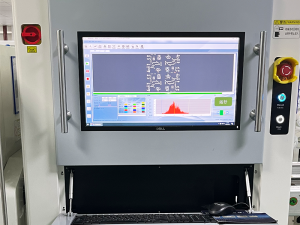

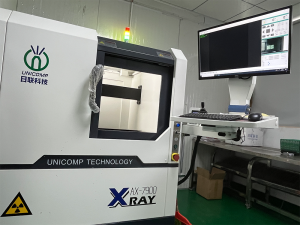

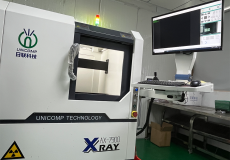

YCT— Advanced Equipment Showcases Exceptional Production Strength

YCT proudly possesses a range of internationally leading production equipment and modern manufacturing processes. Our factory is equipped with high-precision SMT placement machines, fully automatic AOI optical inspection devices, X-Ray inspection machines, reflow soldering machines, wave soldering machines, and other cutting-edge equipment. These advanced machines enable us to efficiently and accurately complete various PCB assembly tasks, ensuring product quality meets the highest industry standards.

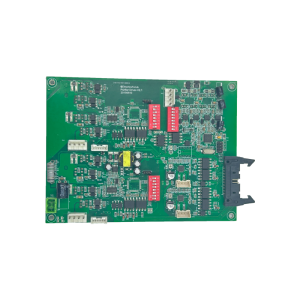

A Reliable Manufacturer

Solder Paste Printing Test

PCB Assemble

Strict Inspection

YCT—PCB Assembly Manufacturing Standards

Our experienced technicians will always ensure that all products are of exceptional quality,reliability and consistency.

| PCB Assembly Parameters | Bulk Order Supported Capabilities | Sample Order Supported Capabilities |

|---|---|---|

| PCB size | L50xW50mm~L510xW460mm | Unlimited |

| PCB thickness | T=0.4~4.0mm | Unlimited |

| Min SMD size | 01005(inch) | 01005(inch) |

| Max SMD size | 45x45mm(Connector length:150mm) | Unlimited |

| Min IC Pin Pitch | 0.3mm | 0.3mm |

| Min BGA Ball Pitch | 0.4mm | 0.4mm |

| Equipment placement accuracy | ±0.35mm @3σ | ±0.35mm @3σ |

| SMD production capacity | 1000K points/day | 200 Orders/day |

| DIP production capacity | 500K points/day | 200 Orders/day |

YCT—Quality Control Process

The perfect quality assurance system and various testing equipment help us monitor the entire production process to ensure the stability of the process and product quality. At the same time, we also introduce advanced instruments and technical methods to achieve continuous improvement.

YCT has dozens of SMT production lines. Advanced production equipment, strict quality control and intelligent service system to ensure the standardization and best quality of each production process

Smart management system & Advanced production and testing equipment

Quality checking process and description

01-Process review

Assess and inspect the particularity of the PCBA manufacturing process in advance, guide the production, and improve the quality from the process technology.

02-IQC Incoming Quality Control

● Check whether the resistance and capacitance values are correct ● Check whether the pads on the components and the board are consistent ● Confirm whether the incoming quantity is accurate ● Check whether the components are abnormal

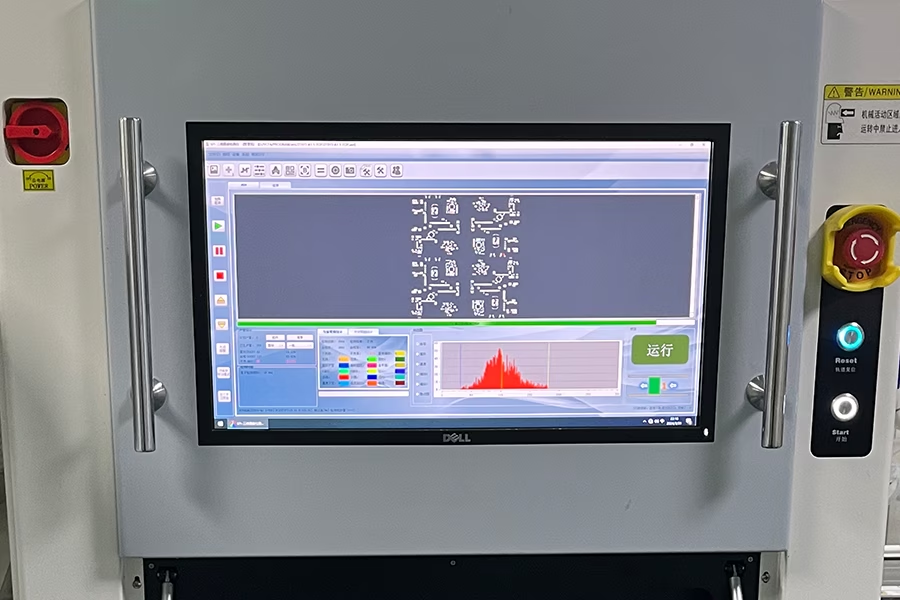

03-SPI Solder Paste Inspection

SPI can detect whether the solder paste is sufficient and uniform, which can effectively prevent production quality problems in advance caused by poor solder paste printing.

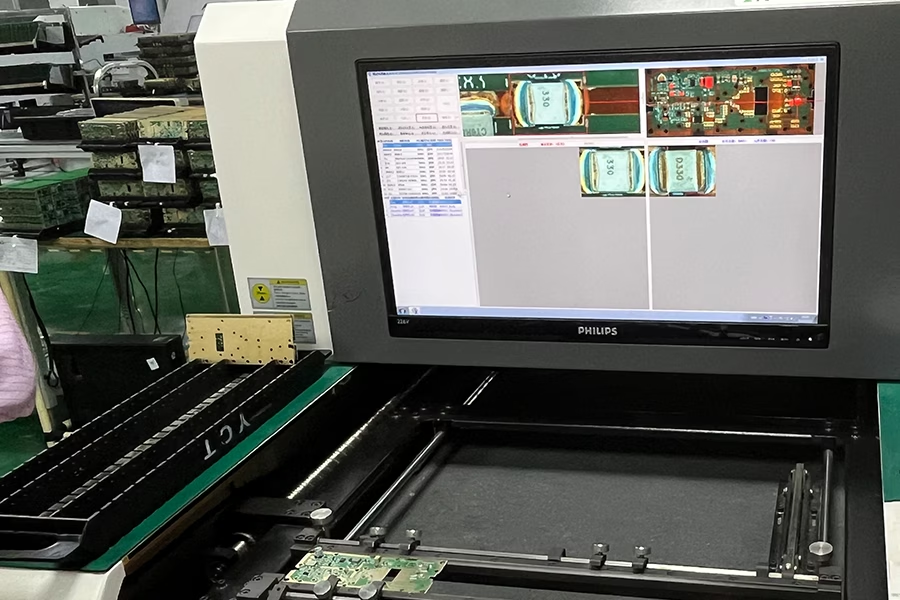

04-Online AOI Inspection

The AOI can detect the wrong solder, reverse solder, false solder, empty solder, incomplete solder, short circuit, offset, tombstone, etc. after reflow soldering. And it can also detect excessive solder, less solder, continuous solder and other undesirable phenomena in the appearance of PCBA solder joints.

05-First sample test

Combined with Gerber, BOM and coordinate files, the resistance and capacitance in the completed PCBA are verified again by the first-sample tester to ensure the correctness of all parameter values.

06-Off-line AOI inspection

According to the IPC610D standard, inspect the soldered surface mount PCBA for errors, omissions, and false connections.

07-X-Ray welding inspection

Inspect the solder joints of invisible components to ensure the reliability of each solder ball of the BGA.

08-QC manual inspection

Refers to the standard IPC--610 inspection standard, and the finished board is visually inspected to ensure 100 % Good products shipped.

Who Need PCB Assembly

Any electronic product will need PCB assemble

Consumer Electronics

Companies producing various consumer electronic products, such as smartphones, tablets, smart home devices, and wearables.

Automotive Electronics

Manufacturers of various electronic control units (ECUs), sensors, navigation systems, and infotainment systems in vehicles.

Telecommunications

Companies manufacturing communication devices like routers, switches, base stations, and satellite communication equipment.

Medical Equipment

Manufacturers of medical devices, including monitoring equipment, diagnostic devices, and other precision electronic medical equipment.

Industrial Control

Companies involved in producing industrial automation equipment, sensors, PLC control systems, and robotic control systems.

Aerospace and Defense

Manufacturers of avionics, satellite systems, missile control systems, and other defense-related electronic equipment.

See What Others Are Saying

FAQ

Most frequent questions and answers

We provide turnkey solution including PCB design, Software development, PCB Assembly, Enclosure design, Mold-making,Plastic injection, Finish product assembly and function testing.

Our PCB/PCBA services are mainly for the industries including Industrial control, Home appliances main boards,automotive electronics, Consumer electronics, Medical equipment, bank equipment, smart home etc.

PCBAYCT is a 15-year experienced professional contract manufacturer to provide one stop Turnkey PCB assembly and electronics manufacturing service.

For OEM PCBA projects, please provide the Gerber data/files and indication of related technical requirements as well as any special requirement if you have; For ODM projects, please provide Function List, so our engineer team can work on it.

Depend on project’s complexity. Normally 1-2 week is enough for our engineers to evaluate.

No, we do not have MOQ requirement, we can support your projects starting from prototypes to mass productions.

Contact us

to Begin your Bessiness