Table of Contents

近期文章

Turnkey PCB Assembly: A Complete Guide

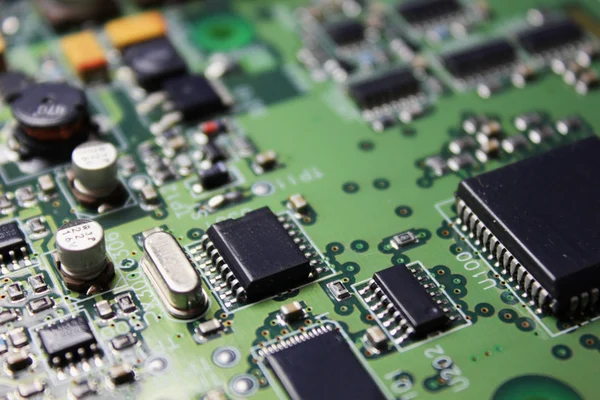

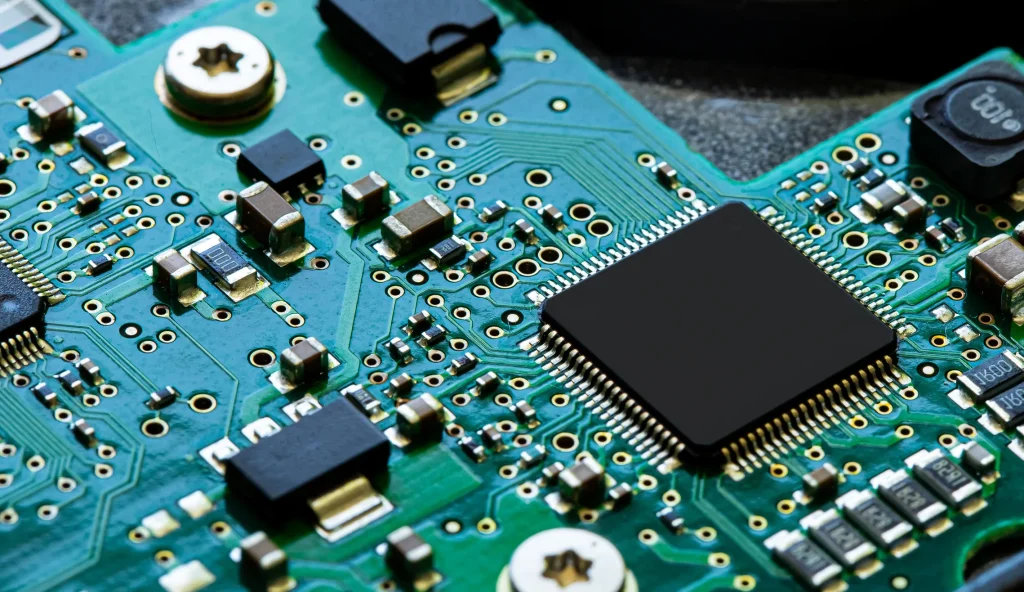

Printed-circuit-board assemblies (PCBAs) are the functional heart of almost every electronic product, from smart phones and medical devices to aerospace and defense systems. As product portfolios expand, features grow more complex and time-to-market windows shrink, manufacturers are increasingly adopting turnkey PCB assembly to gain a competitive edge. By outsourcing every production stage to a single specialist, they can compress development schedules, cut costs and accelerate volume ramp-up. This article explains in detail what turnkey PCB assembly is, how it works and why it has become the preferred model for many hardware companies.

What Is Turnkey PCB Assembly?

Turnkey PCB assembly is an end-to-end, one-stop PCB assembly service in which a single vendor is responsible for the entire production chain—component sourcing, bare-board fabrication, SMT/THT assembly, inspection, functional test, final packaging and shipping. Customers only need to provide the design package (Gerber files, BOM, assembly drawings); the turnkey PCB assembly contractor delivers fully tested boards ready for integration into the final product.

Key Elements of Turnkey PCB Assembly

- Design Review (DFM/DFT): Dedicated engineers scrutinize Gerber, BOM and pick-and-place files to ensure manufacturability, testability and early detection of potential design flaws.

- Component Sourcing: Leveraging an authorized supply-chain network, the turnkey PCB assembly provider procures all parts, guaranteeing authenticity, lead time and cost targets.

- PCB Fabrication: Bare boards are produced strictly to specification—layer count, laminate material, copper weight, surface finish—under IPC-A-600 or higher standards.

- Assembly: Automated SMT lines, selective soldering and wave soldering handle everything from 01005 passives to fine-pitch BGAs and stacked micro-BGAs.

- Testing & Quality Control: AOI, X-ray, ICT and functional test ensure the turnkey PCB assembly output meets or exceeds customer requirements.

- Packaging & Logistics: Cleaned boards are ESD-safe packaged, optionally box-built, and shipped worldwide with full traceability documentation.

Standard Turnkey PCB Assembly Process

Step 1 – Initial Communication & Quotation

The customer submits Gerber, BOM, assembly drawings and special requirements. The turnkey PCB assembly house analyzes the data and issues a detailed quotation covering tooling, fabrication, components, assembly and test.

Step 2 – Design for Manufacturability Review

Engineers review pad-to-pad spacing, solder-mask clearance, footprint matching and test-point allocation to confirm manufacturability and head off costly respins.

Step 3 – Component Procurement

Part numbers are cross-checked for EOL status; form-fit-function alternates are proposed when necessary. All components are sourced directly from OEMs or franchised distributors to block counterfeit risk. Customer approval is required before any substitution in the turnkey PCB assembly flow.

Step 4 – PCB Manufacturing

Material, layer stack-up and finish (ENIG, OSP, immersion silver, etc.) are selected per design intent, thermal requirements and IPC class.

Step 5 – Assembly

Stencil printing, high-speed pick-and-place, reflow/wave/ selective solder complete SMT and through-hole operations. The turnkey PCB assembly line can handle HDI, rigid-flex, high-layer-count or high-frequency builds.

Step 6 – Inspection & Test

- AOI verifies solder paste volume, part orientation and tombstoning.

- X-ray inspects concealed joints on BGA, QFN and stacked packages.

- ICT measures continuity, resistance, capacitance and in-circuit programming points.

- Functional test simulates real-world application loads to guarantee performance.

Step 7 – Final QC, Packaging & Shipment

Qualified boards undergo cleaning, conformal coating if specified, ESD packaging and final documentation before on-time dispatch. A complete turnkey PCB assembly report with trace codes accompanies each lot.

Service Variants of Turnkey PCB Assembly

- Full Turnkey PCB Assembly:The provider handles everything from procurement to final test and logistics. Ideal for start-ups or companies seeking maximum simplicity.

- Partial/Consigned Turnkey PCB Assembly:The customer consigns some or all components; the supplier covers the remaining manufacturing and assembly steps. Suitable for firms that already stock critical parts or need tight control of key ICs.

- Hybrid Turnkey PCB Assembly:Responsibilities are flexibly split project-by-project—for example, vendor buys passives while the customer supplies custom ASICs.

Benefits of Turnkey PCB Assembly

- Streamlined Project Management: One point of contact eliminates coordination among multiple vendors and minimizes admin overhead.

- Faster Time-to-Market: Consolidating DFM, procurement, fabrication and assembly in a unified workflow shortens lead time dramatically.

- Lower Total Cost: Volume purchasing power and reduced logistics touchpoints cut component and handling expenses.

- High Quality & Reliability: ISO-certified processes, authorized component sources and comprehensive test coverage yield highly reliable boards.

- Risk Mitigation: Proactive material forecasting, substitute validation and SPC/FMEA at the manufacturing stage reduce shortages and field failures.

- Focus on Core Competence: Internal teams can concentrate on R&D, branding and sales while the turnkey PCB assembly expert manages production complexity.

How to Select a Turnkey PCB Assembly Manufacturer

- Experience & Reputation:Examine years in business, case studies, customer testimonials and certifications such as ISO 9001, ISO 13485 or AS9100.

- Technical Capability:Confirm the factory can build HDI, ultra-fine-pitch, high-layer or specialty-material boards and provides robust DFM/DFT feedback.

- Quality Assurance:Look for complete test coverage—AOI, X-ray, ICT, flying-probe, functional and burn-in—and an auditable corrective-action system.

- Procurement & Supply Chain:Verify that all parts come from OEM-authorized channels with full traceability to fight counterfeits in the turnkey PCB assembly pipeline.

- Communication & Support:Choose a partner offering dedicated project managers, multilingual engineering support and 24-hour response.

- Flexibility & Scalability:The ideal turnkey PCB assembly vendor should scale seamlessly from NPI prototyping to high-volume production, offer firmware flashing, box-build and global logistics.

FAQ

Q: What is the core difference between Full Turnkey PCB Assembly and Partial Turnkey?

A: In a Full Turnkey model, the supplier is responsible for the entire workflow—component sourcing, PCB fabrication, SMT/THT assembly, testing, and even international logistics. With Partial Turnkey, the customer provides some or all critical components, and the manufacturer handles only the remaining stages. Full Turnkey suits companies that want to simplify supply-chain management and shorten lead time, whereas Partial Turnkey is ideal for firms that must retain control over key ICs or already hold inventory.

Q: Is there any minimum order quantity (MOQ)?

A: Most turnkey PCB assembly vendors support quantities as low as one board for NPI or prototype needs. However, when the run is fewer than 5–10 units, non-recurring engineering (NRE) costs—such as tooling, stencils, and fixtures—are spread across very few boards, making the unit price relatively high. In mass production, the typical MOQ is 100–300 units, which significantly lowers the per-board cost.

Q: How do suppliers ensure that the purchased components are genuine?

A: A reliable turnkey PCB assembly provider sources parts only from OEMs or franchised distributors, with every lot accompanied by a Certificate of Conformance (CofC) and lot code. Before warehousing, incoming parts undergo XRF analysis, microscopic inspection, or even decapsulation tests. A traceability system (ERP plus barcode) records batch and date codes, and a full incoming inspection report is available for customer review.

Q: What happens if manufacturability issues are discovered during production?

A: During the DFM/DFT review, engineers issue a manufacturability report highlighting issues such as undersized pads, solder-mask bridges, or insufficient test points, along with recommended fixes. After the customer approves the updates and provides revised Gerber/BOM files, the build proceeds to production. If anomalies are still detected during assembly, the line is halted, an 8D process is initiated, and the team collaborates with the customer to evaluate rework or design revisions, preventing large-scale defects.

Q: How is the customer’s design confidentiality and intellectual property protected?

A: A compliant factory signs a mutual NDA and implements multi-level access control through its MES system. SMT programs and pick-and-place coordinates are stored in encrypted form and erased once production is complete. Facility access requires badge control and is monitored by cameras, ensuring that both data and physical boards remain secure.

Barry Ding

SEO

About us

We are Yongchangtai Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact us

to Begin your Bessiness