What is the Meaning of PCBA—Printed Circuit Board Assembly?

What is PCBA?

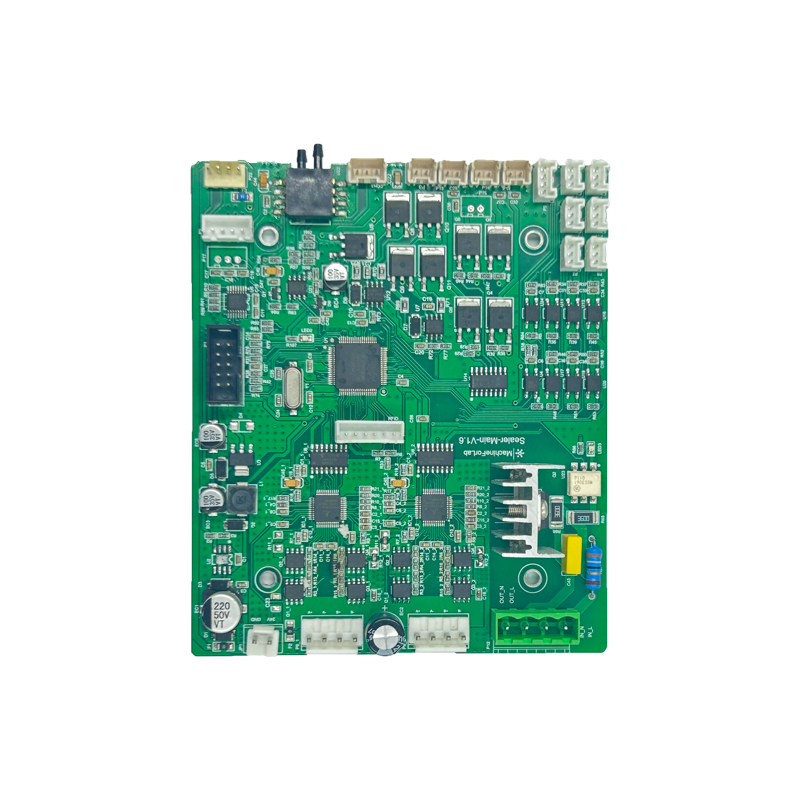

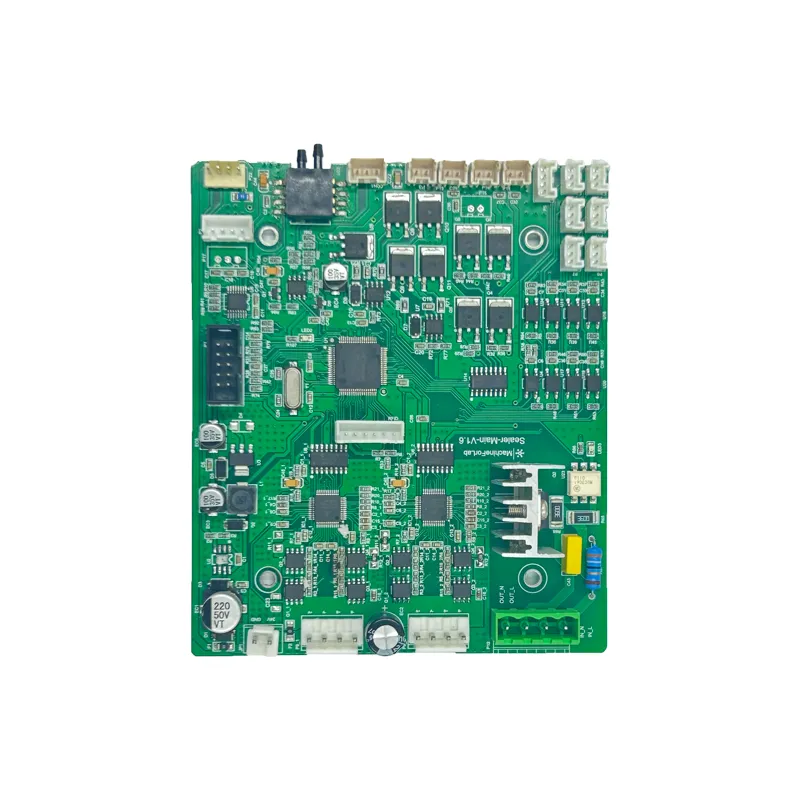

PCBA, short for Printed Circuit Board Assembly, refers to a printed circuit board that has undergone complete component installation and soldering. It represents the full transformation from a blank circuit board (PCB) to a functional module that can power electronic devices.

In simple terms, PCBA is the process of assembling electronic components onto a PCB, making it ready for real-world electronic applications.

PCB Assembly Methods: SMT and THT

There are two primary PCB assembly techniques used in the electronics industry:

1. Surface Mount Technology (SMT)

Components are mounted directly onto the surface of the PCB.

SMT is fast, cost-effective, and highly automated, making it ideal for compact and lightweight devices like smartphones and wearable electronics.

2. Through-Hole Technology (THT)

Component leads are inserted into pre-drilled holes and soldered on the opposite side of the PCB.

THT provides stronger mechanical connections, which is why it’s still used in heavy-duty electronics such as power supplies, industrial machinery, and automotive electronics.

Why PCBA is Crucial in Electronic Manufacturing

PCBA is the core of every electronic device. Without it, circuits can’t operate and signals can’t be transmitted.

Key Advantages of PCBA in Manufacturing:

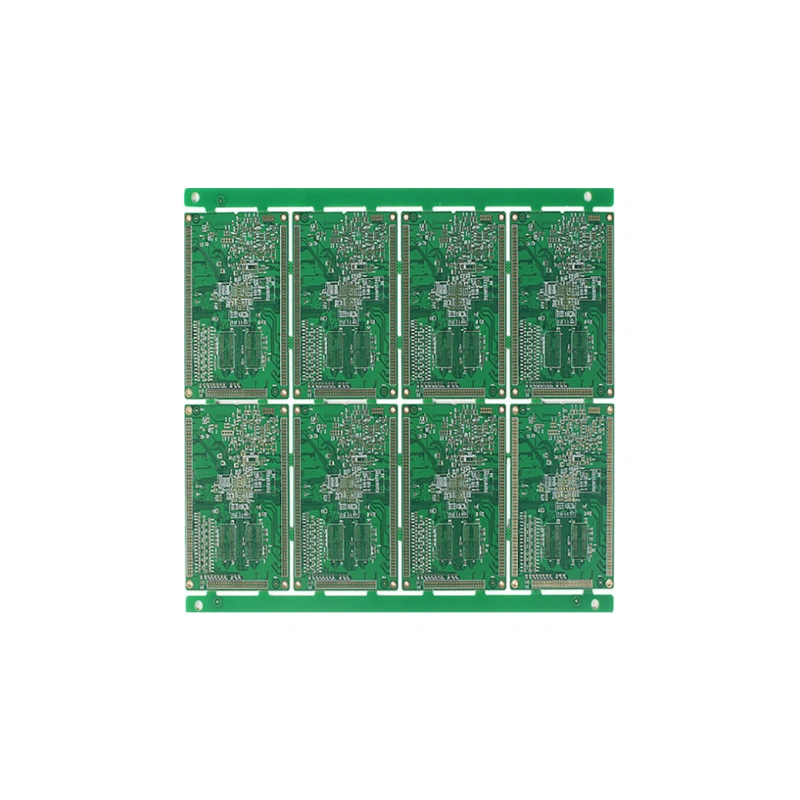

Mass Production: Thanks to automation and standardized processes, modern PCBA manufacturers can produce thousands of fully functional circuit boards daily with high accuracy.

Reliability & Durability: Using techniques like AOI (Automated Optical Inspection), manufacturers ensure that every board meets strict quality standards.

Speed and Efficiency: Automated PCBA allows for rapid production of electronics at scale, helping businesses meet market demand quickly.

PCB vs. PCBA: What’s the Difference?

PCB (Printed Circuit Board): A bare board with copper traces, but no components installed.

PCBA (Printed Circuit Board Assembly): A fully assembled board with all necessary electronic components mounted and soldered, ready to function.

Think of a PCB as an empty bookshelf, and a PCBA as the same shelf fully stocked with books.

Key Technologies in PCBA

PCBA involves the use of two major technologies:

SMT (Surface Mount Technology)

This method involves placing surface-mount devices (SMDs) directly onto the PCB surface. It is widely used in modern electronic products due to its compactness and efficiency.

SMT Assembly Process:

Apply solder paste to the PCB pads.

Perform solder paste inspection (SPI).

Use a pick-and-place machine to mount components.

Pass the board through a reflow oven to melt the solder and secure components.

Clean any residual flux or harmful substances.

Perform quality checks using AOI and X-ray inspection.

Final stage: In-Circuit Testing (ICT) ensures all circuits work properly.

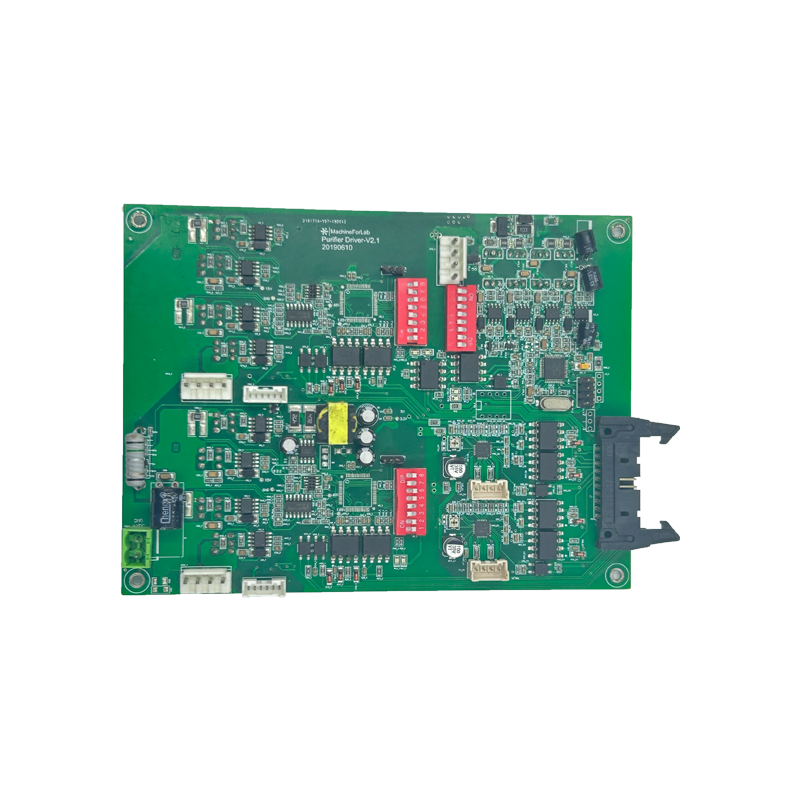

THT (Through-Hole Technology)

THT involves drilling holes in the PCB and inserting component leads, which are soldered on the opposite side. Though less common in today’s consumer electronics, it remains essential for products requiring high mechanical strength.

Applications of THT:

Automotive electronics

Industrial control systems

Power modules

Home appliances like televisions and chargers

Top PCBA Manufacturer: PCBAYCT

(top 10 pcb assembly manufacturers in china)

PCBAYCT is one of China’s leading PCBA manufacturers, offering full-process services including:

Technical support

Mass production

Quality control

Supply chain sourcing

With high-quality PCB assembly services, PCBAYCT helps customers accelerate their electronic product development. For professional buyers and engineers, PCBAYCT is a trusted and efficient manufacturing partner.

Conclusion

PCBA is the critical process of turning a bare PCB into a functional electronic board. Using SMT and THT technologies, manufacturers can create reliable, high-quality circuit assemblies that power the world’s electronics.

Choosing the right PCBA manufacturer ensures success in your electronic projects. Work with PCBAYCT to bring your next innovation to life.

FAQ

1. What is circuit board assembly?

Circuit board assembly involves placing components like SMDs, ball grid arrays (BGA), and quad-flat packages on a PCB or motherboard. This process can include selective soldering, using soldering paste to make solid connections.

2. How does component placement work in the assembly process?

Component placement in circuit board assemblies involves accurately positioning surface mount components and other elements onto the mainboard. The use of tools like an SMT stencil helps ensure precision.

3. Can you describe some testing methods used after assembling a circuit board?

Testing methods may involve checking for leakage current, ensuring proper capacitance levels, or conducting embedded system testing to verify all components function correctly together.

4. What materials are commonly used during a circuit card assembly?

Common materials include solders for creating electrical connectors, epoxy for securing components into place through holes or plated through-hole techniques, and deionized water for cleaning purposes before applying spray coatings.