Table of Contents

近期文章

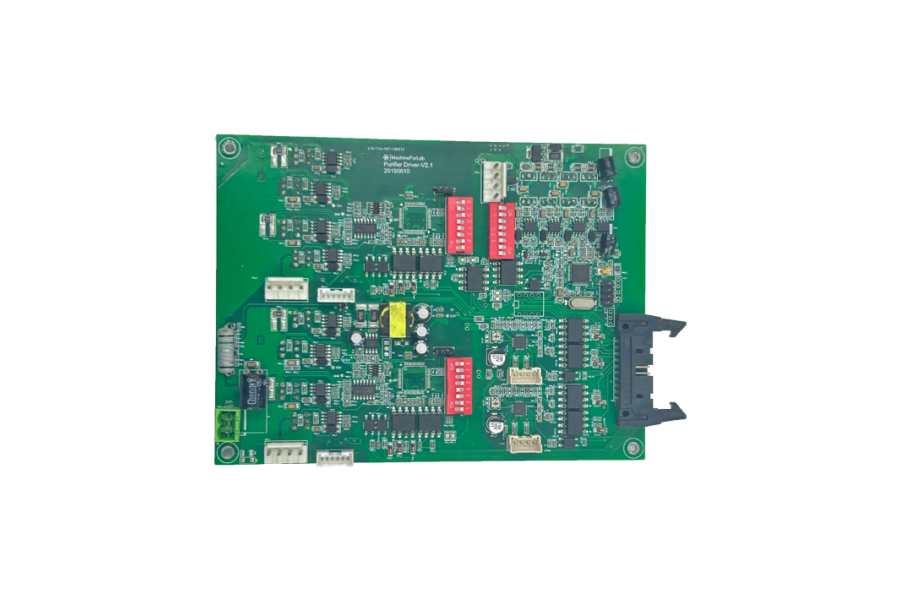

A Complete Guide to Medical PCBA: Function, Importance, and Applications

Growth is driven by the relentless demand for advanced diagnostic and monitoring equipment, expanded healthcare infrastructure and sustained government investment in medical technology.

Definition

A Medical PCBA (Medical Printed Circuit Board Assembly) is a fully populated circuit board engineered specifically for medical electronics. It combines an insulating substrate (PCB) etched with copper traces and a host of electronic components—micro‑controllers, capacitors, resistors, sensors and integrated chips—to deliver the core functions of life‑critical devices.

Unlike consumer‑grade assemblies, medical PCBAs must withstand far stricter reliability, safety and regulatory scrutiny; even a tiny design flaw can cause device failure with serious clinical consequences.

Core Building Blocks

| Functional Block | Role in Medical Devices |

|---|---|

| Microcontroller / Processor | “Brain” that processes sensor data, executes embedded firmware and guarantees real‑time responsiveness. |

| Sensors | Measure vital parameters such as heart rate, SpO₂, blood glucose and temperature; must offer high accuracy, low drift and fast dynamic response. |

| Connectors & Terminals | Provide robust, low‑noise interfaces between modules or peripherals and allow rapid mating/demating in harsh clinical settings. |

| Capacitors & Resistors | Stabilise voltage/current, filter noise and ensure signal integrity in precision analog and digital paths. |

| Integrated Circuits (ICs) | Handle A‑to‑D conversions, signal amplification, wireless communication and data storage. |

| Power‑Management Devices | Deliver clean, isolated and fault‑tolerant power; often based on low‑noise PMICs or full battery‑management systems (BMS). |

Industry‑Specific Requirements

Quality & Reliability

“Near‑zero‑defect” targets (< 100 ppm) and mandatory inspection chain: SPI → 3‑D AOI → X‑ray.

Materials & Process Control

High‑Tg, low‑toxicity laminates; lead‑free, biocompatible solders.

Clean‑room or ESD‑safe environments; precision SMT lines capable of 01005 parts with ± 0.025 mm placement accuracy.

Environmental Robustness

Endure –40 °C cold‑chain transport, 85 % RH operating theatres, repeated sterilisation and chemical exposure.

Verified through temperature‑cycling, vibration and salt‑spray tests.

Regulatory Compliance

Ensuring Medical‑Grade Quality

| Stage | Key Actions |

|---|---|

| Design | Plan board size, layer stack‑up, component layout, EMC shielding and thermal paths with ISO 13485 / IEC 60601 design controls. |

| Material Selection | Source certified laminates, components and solder pastes; audit critical suppliers regularly. |

| Manufacturing | Control temperature, humidity and time parameters; employ advanced SMT & PTH, reflow profiles and AOI/X‑ray to catch defects early. |

| Testing | Conduct cosmetic, functional, ICT/FCT and environmental stress tests to verify conformance to specifications. |

| Quality Management | Operate under an ISO 13485‑compliant QMS; maintain controlled documents, CAPA and continual improvement loops. |

| Traceability & Feedback | Record lot codes, process parameters and serial numbers for full backward traceability and rapid field‑failure analysis. |

| Packaging & Logistics | Use moisture‑barrier, ESD‑safe and shock‑resistant packaging; monitor conditions through transit. |

Key Standards & Regulations

ISO 13485 – Quality‑management systems for medical devices.

IPC‑A‑610 Class 3 – Acceptability requirements for high‑reliability electronic assemblies.

IEC 60601‑1 – General safety and essential performance for medical electrical equipment.

RoHS Directive – Restricts hazardous substances (Pb, Hg, Cd, etc.).

UL (Flammability) – Material and electrical safety ratings.

Typical Applications

| Segment | Representative Devices |

|---|---|

| Diagnostic | MRI, CT, X‑ray, blood analysers, DNA sequencers, ultrasound scanners |

| Monitoring | ECG/EKG, blood‑pressure monitors, SpO₂/EtCO₂ modules, glucometers |

| Implantable | Pacemakers, ICDs, neuro‑stimulators, insulin pumps |

| Therapeutic | Infusion pumps, dialysis machines, ventilators, surgical lasers |

| Wearable / Home‑Care | Medical‑grade wristbands, mobile ECG patches, smart thermometers |

| Surgical / Hospital | Electrosurgical units, bed‑control systems, endoscopes, robotic surgery platforms |

Choosing the Right Medical PCBA Manufacturer

China hosts thousands of PCBA firms; selecting the right medical‑grade partner is critical. PCBAYCT offers:

15 years of professional experience in healthcare electronics

8 high‑speed SMT lines (01005 capable)

ISO‑aligned quality system and full‑process traceability

Dedicated compliance and documentation support to keep projects on time and on budget

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact Us

to Begin Your Bessiness