Table of Contents

近期文章

PCBA Inspection and Acceptance Criteria: A Comprehensive Guide

Why PCBA Inspection Matters

Modern PCBA inspection is more than a quality gate; it is the backbone of product reliability, safety, and brand trust.

Reliability – Detects early faults so assemblies survive the full service life—even in harsh automotive or industrial controls.

Safety – Prevents latent defects that could endanger patients, drivers, or flight crews.

Compliance – Confirms boards meet IPC-A-610 and customer-specific PCBA acceptance criteria, avoiding legal or market barriers.

Cost control – Fixing issues during PCB assembly inspection is far cheaper than field recalls.

Brand reputation – Consistent quality turns first-time buyers into long-term partners.

Core PCBA Inspection & Test Methods

| Method | Key Focus | Typical Long-Tail Keyword |

|---|---|---|

| Manual / Visual Inspection | Cracks, scratches, solder bridges, polarity errors | visual PCBA inspection checklist |

| AOI Inspection PCB | High-speed cameras flag missing parts, tombstones, insufficient solder | automated optical inspection PCBA |

| Solder Paste Inspection SPI | Measures paste height, volume, offset before placement | solder paste inspection SPI guidelines |

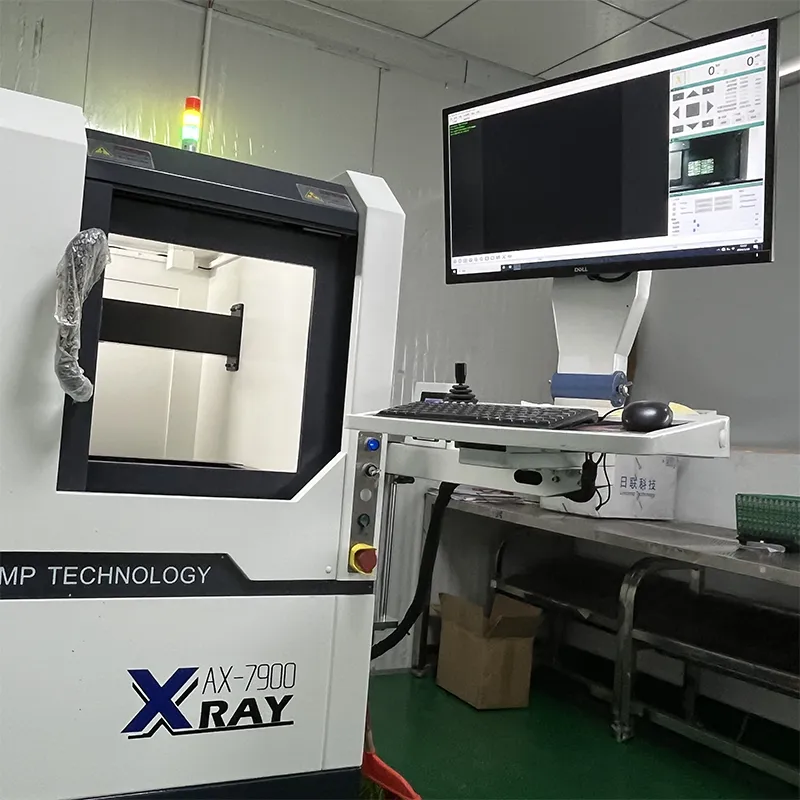

| X-ray BGA Inspection | Finds hidden voids, open joints, inner-layer shorts | X-ray BGA inspection standards |

| ICT (In-Circuit Test) | Nets continuity, resistance, short-open faults | in-circuit test PCBA |

| Functional Test PCBA | Powers board under simulated load to verify firmware, I/O, comms | PCBA functional test procedure |

| Environmental Reliability Testing | Thermal cycling, vibration, high-humidity aging | environmental reliability testing PCBA |

IPC-A-610 Classes & Acceptance Thresholds

| Class | Typical Application | Quality Expectation |

|---|---|---|

| 1 | Toys, low-cost consumer gadgets | Function over appearance |

| 2 | Computers, industrial controllers | Continuous performance, moderate lifetime |

| 3 | Medical, aerospace, automotive safety | Zero-defect mindset, critical reliability |

Appearance & Cleanliness

No surface scratches, warpage or oxidation.

Flux, dust, and fingerprints removed; legend printing legible.

Solder-Joint Quality

Fillets full, shiny, well-wetted.

No voids, cracks, cold joints, or bridges.

Solder volume meets pad-size guidelines.

Component Placement

- Position and polarity correct; no tombstones, lifted leads, or misalignment.

Board Dimensions & Integrity

- Outline, holes, and cut-outs within tolerance; bow/ twist ≤ 1.5 % of length.

Electrical & Functional Performance

- Pass continuity, insulation-resistance, impedance tests; firmware boots; interfaces respond.

Environmental Reliability

- Boards withstand thermal shock, humidity, vibration with no function loss.

Defect Categories & AQL Electronics Levels

| Defect Level | Description | Typical AQL |

|---|---|---|

| Critical (CR) | Safety-related, may cause injury or catastrophic failure | 0 % |

| Major (MA) | Affects function or life | 0.4 % |

| Minor (MI) | Cosmetic only | 0.65 % |

Critical defects are never accepted; major ones trigger rework; minor issues have limited tolerance in Class 1.

Typical End-to-End PCBA Inspection Flow

Incoming Material Check – Bare PCB and component validation.

Solder Paste Inspection SPI – Early control of volume/ alignment.

Pre-reflow AOI Inspection PCB – Confirms part presence & orientation.

Reflow – Controlled thermal profile.

Post-reflow AOI – Flags bridges, cold joints, solder voids.

Manual Sampling – Human eyes cover AOI blind spots.

X-ray BGA Inspection – Deep look at hidden solder balls.

ICT – Electrical shorts/opens, component values.

Functional Test PCBA – Real-world simulation.

Final Visual Audit – Silkscreen, labeling, packaging.

Environmental Reliability Testing – High-stress proof if required.

Common PCBA Defects & Root Causes

Soldering Defects

Cold joint – Dull, grainy surface from inadequate heat or oxidised pads.

Solder bridge – Excess paste or tight pitch.

Insufficient solder – Under-printed paste or poor plating.

Voids – Moist laminate, volatile solvents, wrong reflow profile.

Tombstone – Uneven heating or asymmetrical pad design.

Component Issues

Misplacement, polarity reversal, missing parts, lifted leads—often due to pick-and-place program errors or vibration.

Board-Level Problems

Delamination – Moisture or over-curing.

Warping – Uneven copper, stacking stress, improper storage.

Contamination – Flux residues attract moisture leakage.

Best Practices for High-Yield PCBA Inspection

| Pillar | Actions & Embedded Long-Tail Keywords |

|---|---|

| Design for Manufacturability (DFM for PCB assembly) | Size pads per IPC-7351, leave ICT pads, avoid tall part shadows. |

| Process Control & SPC | Monitor paste height in real time; track PPM trends to spot drifts. |

| Equipment Calibration | Schedule AOI, SPI, X-ray accuracy checks every quarter. |

| Training to IPC-A-610 | Certify operators; refresh when standards update. |

| Traceability | Barcode or RFID every board; log defects and rework to aid continuous improvement. |

PCBA Inspection Quick-Reference Checklist

| Item | Pass Criteria |

|---|---|

| Appearance | No scratches, warps, discoloration, foreign matter. |

| Solder Joints | Smooth, convex, fully wet, no voids or cracks. |

| Components | Correct value, orientation, spacing; no tombstones or missing parts. |

| Dimensions | PCB size within ±0.13 mm; bow/twist ≤ 1.5 %. |

| Electrical Tests | Continuity, insulation-resistance, impedance OK. |

| Functional Tests | All I/O respond; firmware loads; interfaces stable. |

| Environmental Tests | Survive specified temperature, humidity, vibration without degradation. |

Conclusion

Robust PCBA testing—combining SPI, AOI, X-ray, ICT, functional and environmental checks—ensures every assembly meets strict PCBA acceptance criteria. By aligning with IPC-A-610 Class requirements, leveraging AQL electronics guidelines, and enforcing traceable process control, manufacturers slash defect rates and secure long-term customer trust.

PCBAYCT integrates inspection into every design-for-manufacture stage, employs real-time data analytics, and offers full traceability to guarantee Class 3-level reliability.

Ready to elevate your board quality? Contact PCBAYCT for a free DFM review and see how our end-to-end PCBA inspection program can safeguard your next project.

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact Us

to Begin Your Bessiness