PCBA Design and Production Requirements

Printed Circuit Board Assembly (PCBA) forms the backbone of modern electronics, from consumer devices to complex industrial equipment. As an integral part of electronic product manufacturing, understanding PCBA design and production requirements is crucial for ensuring product quality, reliability, and cost-efficiency. This article will explore essential PCBA design guidelines, key production requirements, and best practices to help you streamline your manufacturing processes and achieve excellent outcomes.

What is PCBA?

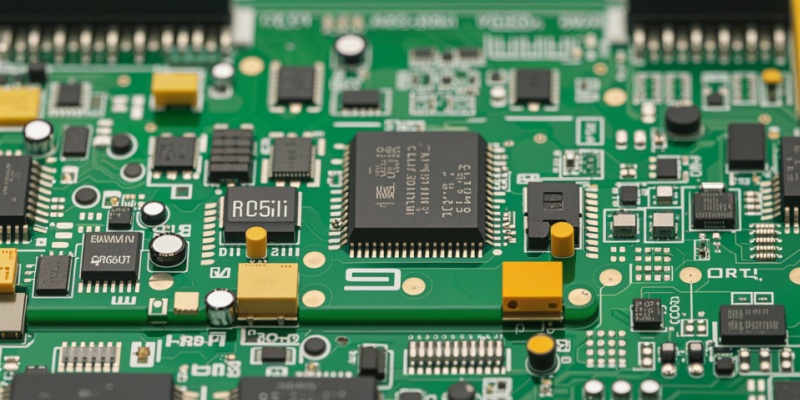

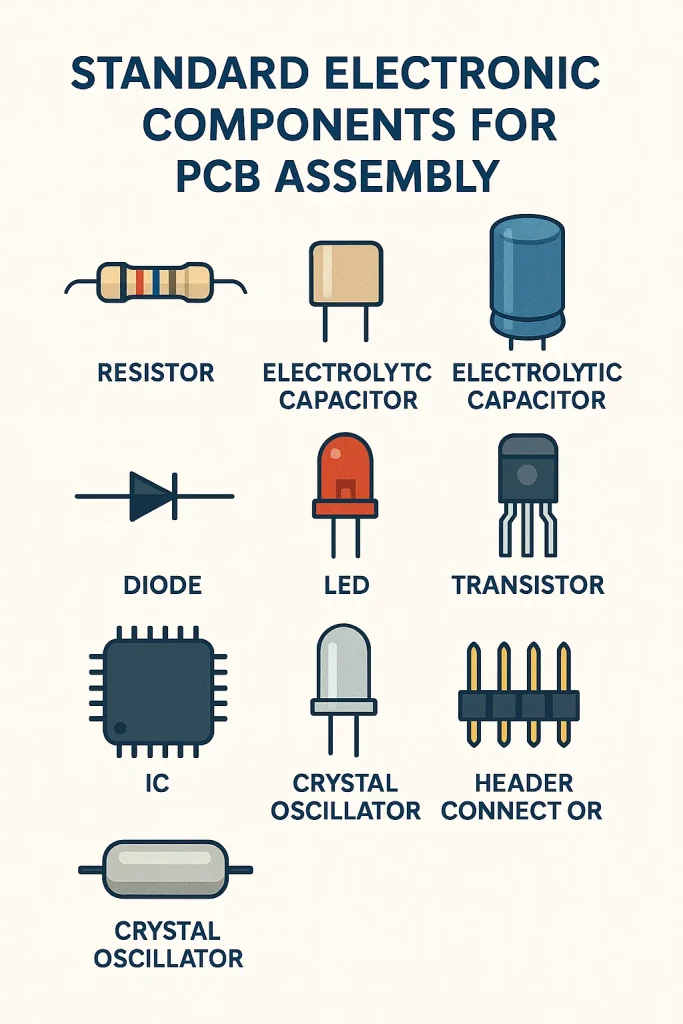

PCBA refers to the process of assembling electronic components onto a printed circuit board (PCB). This involves several stages, including soldering electronic components such as resistors, capacitors, and integrated circuits (ICs) onto the PCB, testing the assembled board, and preparing it for final product integration.

PCBA Design Requirements

Effective PCBA design ensures smoother assembly processes and enhanced performance. Here are essential PCBA design considerations:

1. Component Selection and Availability

Selecting the right electronic components significantly affects your project’s feasibility and cost-efficiency. Factors to consider include:

Availability: Ensure components are readily available from multiple suppliers.

Standardization: Using standard, widely available components reduces supply chain risks.

Compliance: Components should meet regulatory standards (e.g., RoHS, CE).

2. Design for Manufacturability (DFM)

DFM involves designing PCBs to simplify the assembly process, reduce manufacturing errors, and minimize production costs. Key DFM considerations include:

Clearance: Maintain sufficient spacing between components to prevent solder bridging and short circuits.

Component Orientation: Standardize component orientation for consistent soldering.

Testability: Include test points accessible to automated testing equipment.

3. PCB Layer Stack-up and Material Selection

Choosing the right PCB materials and layer configurations is critical for achieving required electrical performance:

Material: Common materials include FR-4, known for its durability and affordability.

Layers: Multilayer PCBs offer enhanced circuit density, improved signal integrity, and reduced electromagnetic interference (EMI).

PCBA Production Requirements

Once the PCB design is finalized, specific requirements ensure high-quality and efficient production:

1. Solder Paste Application

Precise solder paste application is crucial for forming reliable solder joints:

Stencil Design: Proper stencil thickness and aperture size ensure accurate paste deposition.

Inspection: Employ Solder Paste Inspection (SPI) systems to detect anomalies early.

2. Component Placement

Accurate placement of components determines the reliability and functionality of the assembled board:

Pick-and-Place Machines: Automate the placement process for precision and speed.

Alignment Checks: Regular calibration ensures placement accuracy.

3. Soldering Techniques

Different soldering techniques suit varying PCBA needs:

Reflow Soldering: Ideal for Surface Mount Technology (SMT), ensuring uniform heating and consistent solder joints.

Wave Soldering: Suitable for through-hole components, providing strong mechanical bonds.

4. Inspection and Testing

Thorough inspection and testing validate PCBA quality:

Automated Optical Inspection (AOI): Detects visual defects such as misalignment or incorrect solder joints.

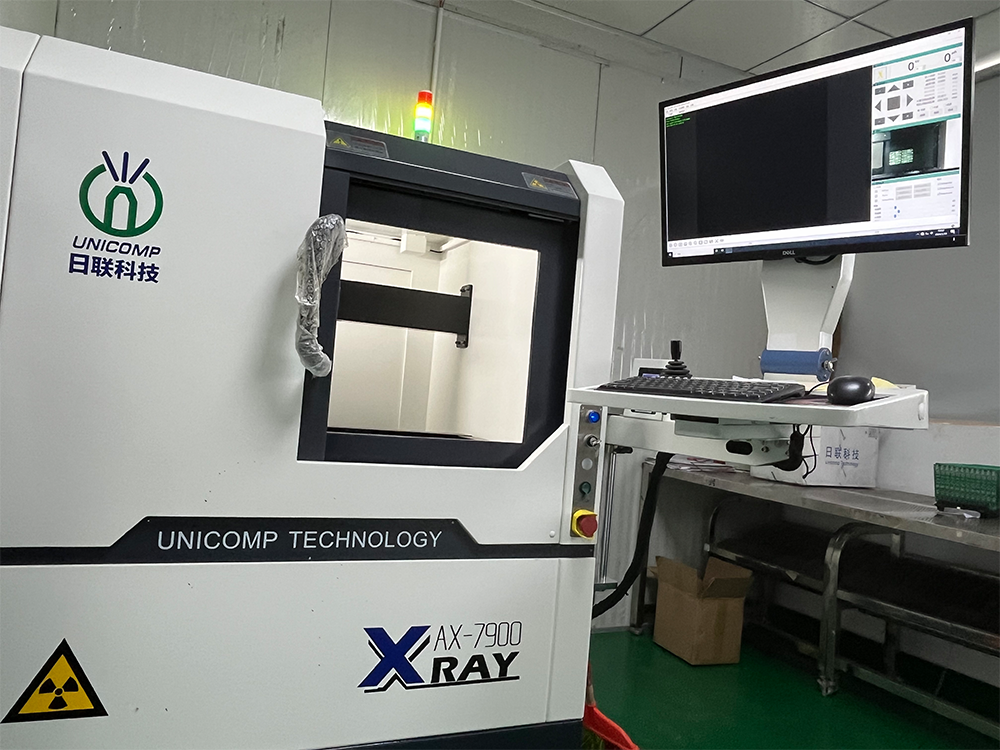

X-ray Inspection: Essential for inspecting hidden solder joints, especially on BGA components.

Functional Testing: Ensures assembled boards meet performance specifications.

Quality Control and Standards

Maintaining strict quality standards ensures reliability and customer satisfaction:

IPC Standards: Adhere to IPC-A-610 standards for acceptability criteria.

Quality Management: Implement ISO 9001-certified processes for consistent quality outcomes.

According to an industry survey by the IPC Association, companies following rigorous IPC standards reported a significant reduction in defect rates—up to 20% lower compared to non-compliant counterparts (source).

Packaging and Handling

Proper handling and packaging safeguard assembled PCBs from damage:

ESD Protection: Use anti-static packaging to prevent electrostatic discharge damage.

Moisture Control: Employ moisture barrier bags with desiccants to avoid moisture-induced failures.

Environmental Considerations

Sustainable practices in PCBA production can significantly reduce environmental impact:

RoHS Compliance: Avoid hazardous substances such as lead, cadmium, and mercury.

Waste Management: Efficiently recycle and manage waste generated during manufacturing.

Common Challenges and Solutions

Understanding common challenges helps in proactive management:

Component Shortages: Maintain robust supplier relationships and alternative sourcing plans.

Design Errors: Implement thorough design reviews and validation procedures.

Conclusion

Meeting PCBA design and production requirements is fundamental for achieving high-quality electronic products. Incorporating strategic design decisions, employing advanced manufacturing techniques, and maintaining stringent quality control can significantly enhance production efficiency and product reliability.

At our specialized PCBA facility, we offer comprehensive PCB assembly services designed to streamline your manufacturing process, ensuring your electronic products meet high industry standards. Reach out to our expert team today for customized support and solutions tailored specifically to your project’s needs.