Table of Contents

近期文章

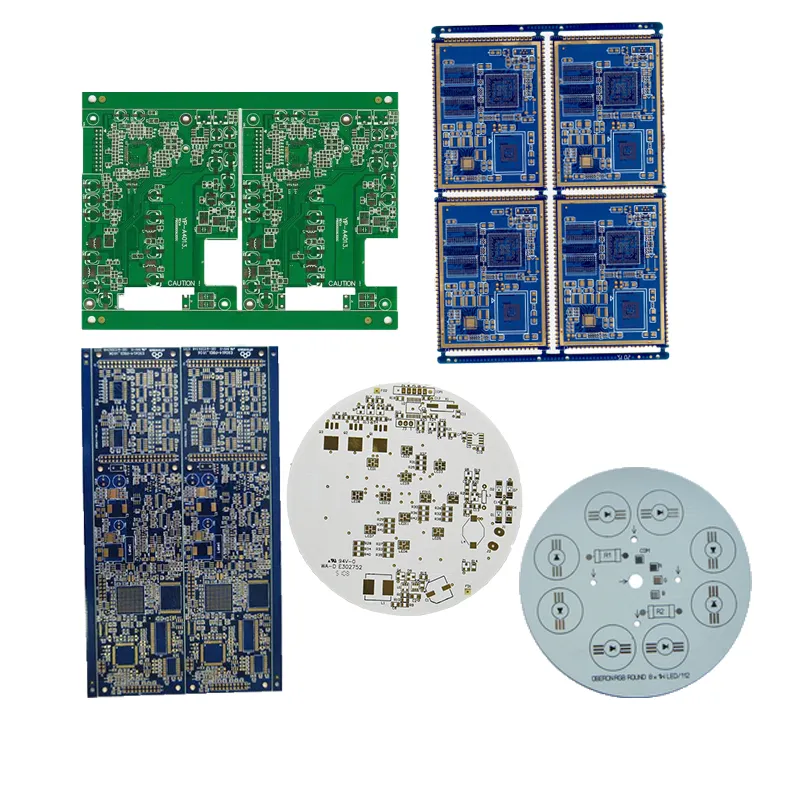

PCB Assembly Cost Explained

PCBA Cost

Total PCBA Cost = Direct Material + Manufacturing & Assembly + Engineering & Quality + Overhead + Logistics & Packaging + Profit

Unit PCBA Cost = Total PCBA Cost ÷ Order Quantity

Direct Material Cost

This is the lion’s share of any PCBA quote and covers the bare PCB, all BOM components, and line-side consumables such as solder paste and conformal coating. Board technology (layers, finish, substrate) and the price volatility of ICs or specialty passives drive the range—typically 55-80 % of total cost.

Manufacturing & Assembly Cost

All shop-floor operations, from SMT placement through DIP/wave solder, reflow, cleaning, and box-build, fall here. Pricing is usually “placement points × rate” for SMT plus labor or joint count for DIP, adding 8-20 % to the bill.

Engineering & Quality Cost

Up-front NRE—DFM reviews, stencil and fixture design—plus ICT/FCT jigs, first-article runs, and in-line inspections (SPI, AOI, X-ray) are pooled in this bucket. Expect 3-8 % of the total, higher for complex or highly regulated products.

Indirect Manufacturing Overhead

Depreciation on SMT lines, utilities, shop-floor IT (MES/ERP), and support staff are collected as a composite hourly rate and allocated by run time. This “factory burden” usually adds another 3-7 %.

Logistics & Packaging Cost

Freight for inbound parts and outbound boards, duties/VAT, and ESD-safe or custom packaging make up 1-5 % of cost but can spike with expedited shipping or oversized assemblies.

Profit

EMS providers apply a cost-plus margin—often 10-30 %—scaled to order size, technical risk, and competitive pressure.

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact Us

to Begin Your Bessiness