Table of Contents

近期文章

High-Temperature PCB Materials: Reliable Solutions for Demanding Environments

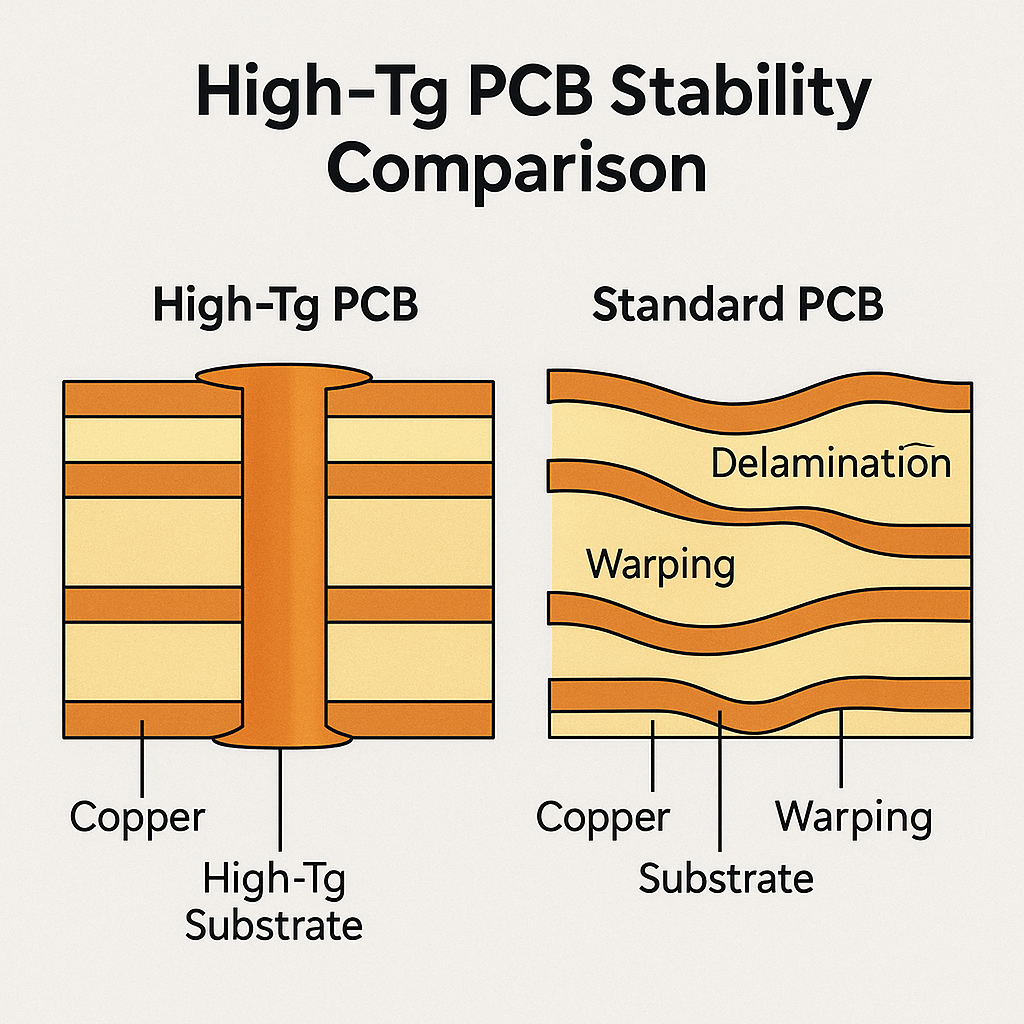

As electronic assemblies operate in higher power densities and more extreme environments, standard FR-4 boards often reach their thermal limits. Components are packed tighter, cooling becomes harder, and boards must resist warping, delamination, and electrical drift under continuous heat.

High-temperature PCB materials—often called high-Tg PCBs—offer enhanced thermomechanical stability and reliability at elevated temperatures. These substrates withstand repeated lead-free reflow cycles and long-term high-temperature operation without compromising electrical performance or mechanical strength.

What Is Tg in PCB Materials?

Tg (glass transition temperature) marks the point where a polymer transitions from a hard, glass-like state to a softer, rubbery one.

- Below Tg, a PCB’s epoxy resin is dimensionally stable and rigid. Above Tg, its molecular structure gains mobility, causing changes in stiffness, expansion rate, and dielectric properties.Example: “Tg170” indicates a glass transition temperature of 170 °C, meaning the material can sustain continuous operation roughly 20–25 °C below that limit.

- Tg is a material property, not the full operational temperature rating, which also depends on additives, resin systems, and copper construction.

Effects of Exceeding Tg

When operating above the glass transition temperature:

- Softening and reduced stiffness lead to potential board deformation.

- Warping and layer misalignment can cause registration errors and mechanical failure.

- Delamination occurs as adhesion weakens between resin and copper.

- Via or PTH cracking increases under cyclic stress.

- Electrical degradation appears as impedance drift and higher signal loss.

Design rule: Keep the maximum continuous temperature 20–25 °C below Tg to ensure stability and predictable behavior during thermal cycling.

What Qualifies as a High-Tg PCB?

A high-Tg PCB uses resins with elevated glass transition temperatures, allowing safe operation under harsher conditions such as RoHS lead-free soldering and high ambient heat.

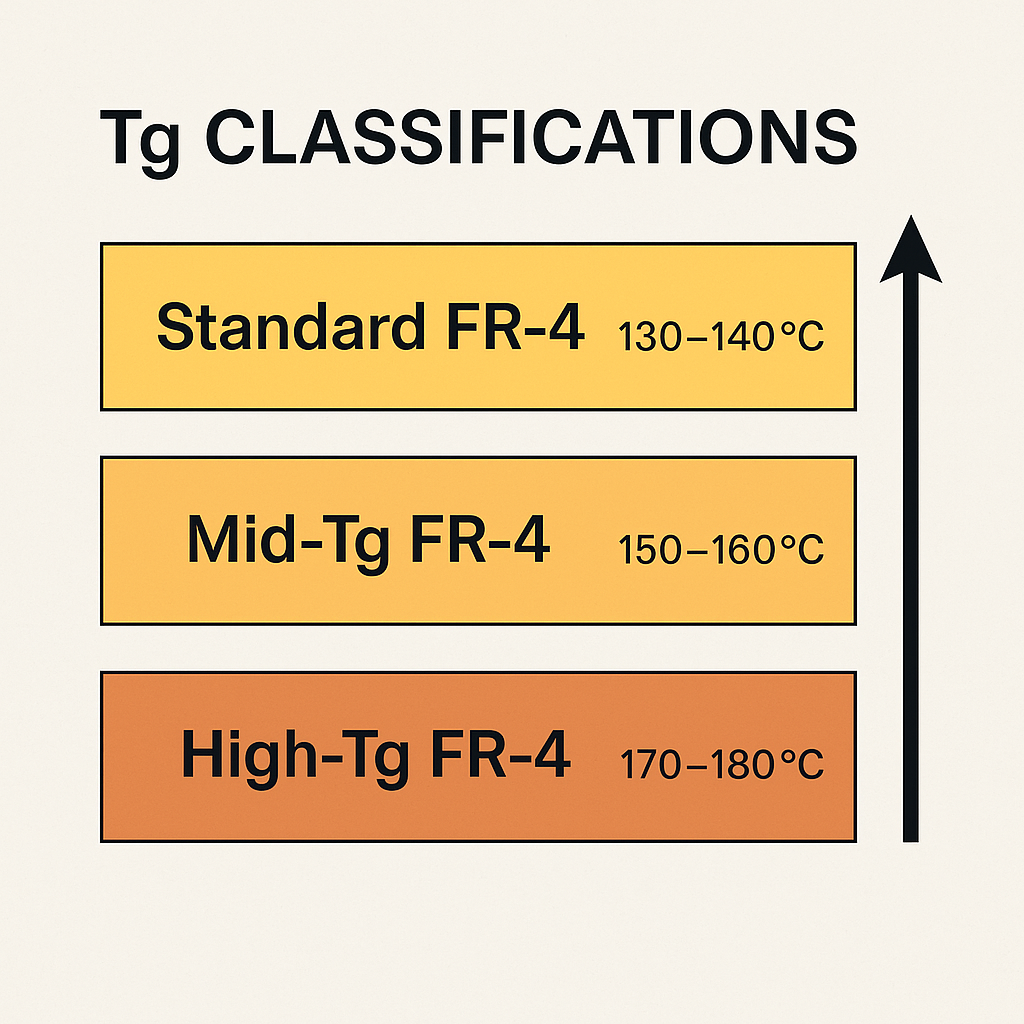

Typical Tg classifications:

Material Type | Typical Tg (°C) | Common Use |

Standard FR-4 | 130–140 | Consumer, office electronics |

Mid-Tg FR-4 | 150–160 | Industrial control, moderate power |

High-Tg FR-4 | 170–180 | Automotive, telecom, server boards |

Polyimide | 200–260 | Aerospace, defense |

PTFE / Rogers 4350B | 200–280 | RF, microwave, 5G applications |

BT Epoxy | 200–250 | IC substrates, high-density modules |

Why High-Tg and High-Temperature PCB Materials Matter

1. Lead-Free Manufacturing (RoHS)

Tin-silver-copper (SAC) solder alloys reflow at up to 260 °C.

High-Tg substrates maintain adhesion, resist warping, and prevent copper pad lifting during these cycles—critical for RoHS-compliant production.

2. Thermal Reliability in High-Power Designs

Power converters, motor drives, and logic-heavy PCBs generate heat that stresses material interfaces.

High-Tg materials minimize thermal expansion and maintain solder joint reliability across temperature cycles.

3. Stability in Multi-Layer & HDI Boards

With dozens of layers and microvias, Z-axis expansion mismatch can cause delamination or cracked vias.

High-temperature PCB materials typically offer low Z-axis CTE, improving via reliability and electrical continuity.

Key Advantages of High-Tg PCB Materials

- Higher thermal limit: Maintains structural and dielectric stability near 180 °C and beyond.

- Low Z-axis CTE: Prevents microvia and through-hole cracking during reflow.

- Reliable interlayer bonding: Reduces delamination risk across thermal cycles.

- Enhanced PTH strength: Ensures long-term reliability for plated through-holes.

- Stable impedance and low signal loss: Supports high-speed or RF designs.

- Excellent moisture and chemical resistance: Ideal for automotive, aerospace, and industrial sectors.

Material Comparison & Typical Applications

Material | Tg (°C) | Strengths | Common Applications |

Standard FR-4 | 130–140 | Low cost, general purpose | Consumer electronics |

High-Tg FR-4 | 170–180 | Cost-effective heat resistance | Automotive ECUs, telecom boards |

Polyimide | 200–260 | High reliability, extreme conditions | Aerospace, military systems |

PTFE / Rogers 4350B | 200–280 | Low dielectric loss | RF/microwave modules |

BT Epoxy | 200–250 | Dimensional stability | IC packaging, power modules |

Industry Applications

Automotive Electronics – Engine control, BMS, and ADAS modules operate near 125 °C ambient; high-Tg FR-4 and polyimide prevent solder fatigue and warpage.

Aerospace & Defense – Polyimide and BT-epoxy materials endure radiation, vibration, and temperature swings.

Telecom & 5G Infrastructure – PTFE-based laminates keep impedance consistent in RF front ends and base stations.

Industrial & Power Electronics – High-Tg FR-4 improves reliability for motor drives, converters, and robotics controllers.

Medical Devices – Moisture-resistant high-Tg substrates tolerate sterilization and extended duty cycles.

Servers & Datacenters – Dense power boards and VRMs depend on low-CTE, high-Tg laminates for stable operation.

Choosing the Right High-Temperature PCB Material

When selecting materials, balance Tg value, CTE, dielectric constant, moisture absorption, and cost.

- Key considerations:Expected continuous operating temperature

- Thermal cycle frequency

- Signal speed and frequency

- Mechanical stress and vibration environment

- Soldering and reflow temperature requirements

Partnering with an experienced PCBA service provider ensures optimal material selection, stack-up design, and processing parameters for long-term reliability.

Conclusion

As electronics evolve toward higher power and density, high-temperature PCB materials are indispensable for achieving durability and performance near thermal limits.

By selecting the appropriate high-Tg substrate—whether FR-4, polyimide, or PTFE—designers can reduce warping, delamination, and electrical drift under harsh conditions.

Integrating these materials within a robust PCBA manufacturing process delivers consistent quality and longevity across automotive, industrial, and aerospace applications.

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact us

to Begin your Bessiness