Table of Contents

近期文章

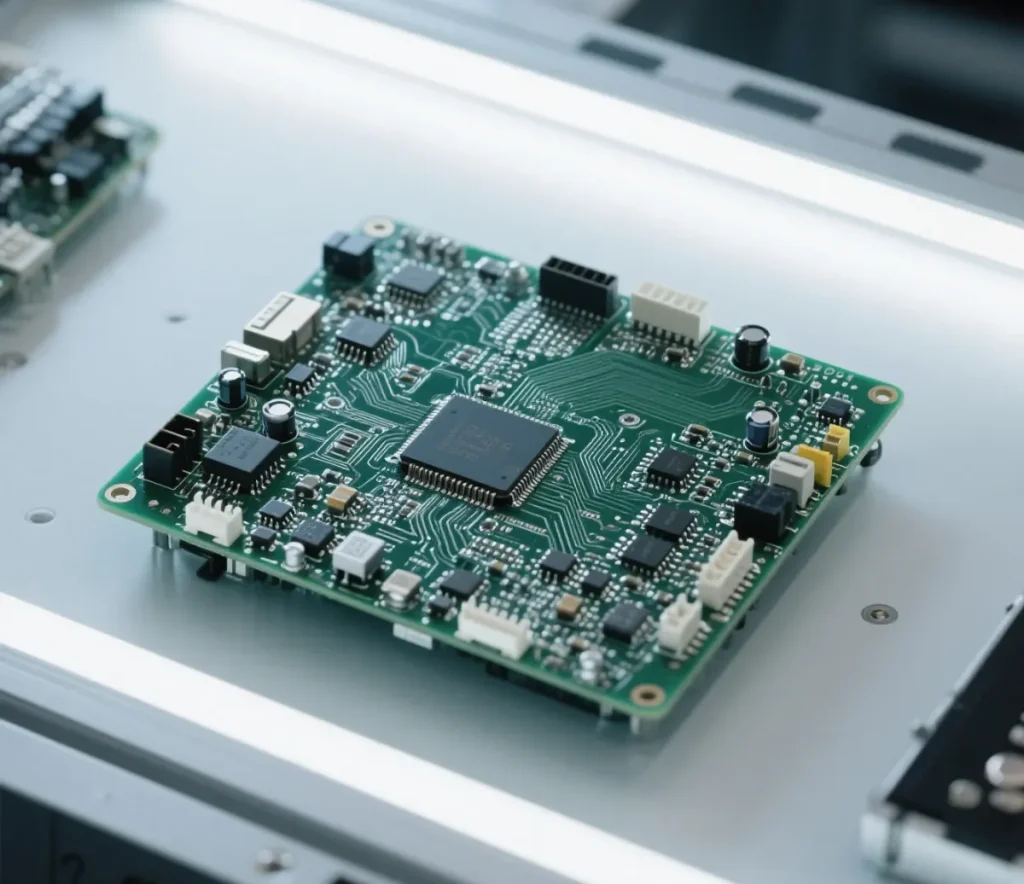

Automotive PCB Assembly – The Core of Modern Vehicle Electronics

Over the past century, vehicles have evolved from simple machines with basic braking systems into highly sophisticated platforms featuring advanced safety, infotainment, autonomous-driving and electrification functions. The common denominator behind all of these features is automotive PCB assembly. By integrating electronic components onto purpose-built circuit boards, automotive PCB assembly enables the performance, safety and comfort that define today’s cars.

What Is Automotive PCB Assembly?

Automotive PCB assembly (also called automotive PCBA) is the process of soldering electronic components onto printed-circuit boards that have been specifically designed for in-vehicle use. The resulting assemblies control or support virtually every electronic function inside a modern automobile.

Why Automotive PCB Assemblies Are Unique

Unlike consumer boards, an automotive PCB assembly must survive extreme operating conditions:

- Wide temperature swings: ‑40 °C winter mornings to 150 °C under-hood hot spots

- Continuous vibration and mechanical shock caused by road dynamics

- Moisture, condensation and splash water, especially near the power-train

- Contact with chemicals such as fuel, oil, coolant and cleaning fluids

- Electromagnetic interference (EMI) from other vehicle systems

Because of these challenges, every automotive PCB assembly is designed, built and tested to stringent standards:

- ISO 26262 – Functional safety for road vehicles

- IATF 16949 – Automotive quality management system

- IPC-6012DA – Performance spec for rigid automotive printed boards

- AEC-Q100/200 – Stress-test qualification for ICs and passive parts

Core Applications of Automotive PCB Assembly

Power-train and Engine Control

- Engine control units (ECU) manage fuel injection, ignition timing, emission control and turbo actuation via CAN or LIN networks.

- Transmission control modules optimize gear shifts, torque converter lock-up and fuel economy.

- Electric power-train in hybrid / EV platforms drives motors, inverters and regenerative braking.

Safety Systems

- Air-bag control modules detect crashes and trigger multi-stage deployments.

- Anti-lock braking systems (ABS) prevent wheel lock-up and shorten stopping distance.

- Electronic stability control (ESC) corrects under-steer or over-steer.

- Advanced driver-assistance systems (ADAS) enable lane keeping, adaptive cruise, blind-spot monitoring and forward-collision warning—laying the groundwork for autonomous driving.

Body Electronics

- Lighting: adaptive LED headlights, tail lights, DRL and ambient interior lighting

- Climate control: HVAC, seat heating / ventilation, steering-wheel heating

- Power windows & mirrors: one-touch lift, memory fold, auto-dimming

Infotainment & Connectivity

- GPS navigation with real-time traffic and over-the-air (OTA) map updates

- Touch-screen displays consolidating media, navigation and vehicle settings

- Bluetooth / Wi-Fi modules for phone mirroring, hands-free calls and hotspots

- Multi-channel audio, active noise cancellation and rear-seat entertainment

Electric-Vehicle (EV) Systems

- Battery-management systems (BMS) monitor cell voltage, temperature and state-of-charge.

- On-board chargers (OBC) handle AC/DC conversion, communicate with charging stations and allocate power.

- Thermal management boards control cooling fans, liquid pumps and heat exchangers.

Sensors and Actuators

- Parking sensors and surround-view cameras provide 360-degree visibility.

- Rain-light sensors control wiper speed and head-lamp activation.

- Pressure, temperature and position sensors feed real-time data to OBD systems for predictive maintenance.

Automotive PCB Assembly Manufacturing Process

Design & Prototyping

- PCB layout includes thermal management, EMI mitigation and mechanical fit.

- Design-for-manufacturability (DFM) reviews prevent downstream defects.

- Early prototypes validate functionality and durability.

Component Sourcing

- Only AEC-Q100/200-qualified semiconductors and passives rated at –40 °C to +125 °C (or wider) are procured.

- Lot codes, date codes and test reports are logged into ERP/MES for full traceability.

PCB Fabrication

- Materials: FR-4 for general use, metal-core or ceramic for high-power modules.

- Stack-ups of 8–12 layers with ±10 % controlled impedance for differential pairs.

- Surface finishes such as ENIG, OSP, lead-free HASL or ENEPIG to balance solderability, corrosion resistance and service life.

Assembly

- Solder-paste printing with SPI feedback controls volume and thickness.

- High-speed placement handles 01005 passives, BGAs, QFNs and PoP packages.

- Reflow for SMT and wave/selective solder for through-hole components, followed by cleaning to remove flux residues.

Inspection & Test

- AOI checks paste volume and joint geometry.

- X-ray measures BGA void ratios.

- In-circuit test (ICT) with flying probes and JTAG verifies electrical connectivity.

- Functional test chambers simulate –40 °C to 125 °C, >10 g random vibration and salt-spray conditions.

Conformal Coating & Potting

- Acrylic, silicone or polyurethane coatings shield the board from dust and chemicals.

- Epoxy or silicone gel potting is applied to inverters and OBCs for enhanced dielectric strength and moisture resistance.

Final Assembly & Integration

- PCBAs are built into larger modules or housings.

- End-of-line (EOL) tests are performed before shipment to OEMs or Tier-1 suppliers.

Conclusion

Automotive PCB assembly is the unseen but critical enabler of the connected, electrified and increasingly autonomous vehicles on today’s roads.

Welcome to contact pcbayct to start your Automotive PCBA project

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact Us

to Begin Your Bessiness