Table of Contents

近期文章

How to Choose the Right PCB Assembly (PCBA) Manufacturer

Selecting the right PCB assembly (PCBA) manufacturer is a critical step to ensure stable product performance, reduce production risk, and accelerate time to market. A reliable partner does more than meet quality requirements. The best manufacturers also support you across component sourcing, engineering, cost optimization, and schedule control, giving your product a long-term competitive edge.

Why Choosing the Right PCBA Partner Matters

A high-quality PCBA manufacturer directly affects your yield rate and brand reputation. Experienced factories typically provide:

Robust quality systems (e.g., ISO 9001, IPC-A-610)

Complete SMT and THT capabilities

Transparent supply chains with anti-counterfeit controls

Responsive engineering and after-sales teams

By contrast, working with unqualified vendors can lead to solder defects, material shortages, rising rework costs, and delays. In severe cases, launches slip and customer satisfaction plummets.

Step 1: Define Your Project Requirements Before Selecting a Supplier

Technical Specifications Checklist

Clarify your PCB and assembly parameters up front:

Board layer count and materials (FR-4, aluminum, flex, etc.)

Component density and special processes (BGA, QFN, RF circuits)

Product lifetime and operating environment (temperature, humidity, EMC)

Prepare a complete BOM, Gerber files, and assembly notes to avoid quote errors and shorten evaluation time.

Production Scale

Identify your stage: prototype, pilot, or mass production. Line setups and inventory strategies vary widely. Large factories often hold cost advantages in mass production, while small and mid-sized manufacturers are more agile for rapid iterations. Availability of a dedicated quick-turn line will largely determine prototype lead time.

Scope of Services

Decide whether you need turnkey service, including:

Component procurement and approved alternatives management

Test fixture development and functional testing

Packaging, logistics, and export customs

An end-to-end partner reduces coordination overhead and improves controllability.

Step 2: Evaluate Manufacturing and Assembly Capabilities

Equipment and Technical Maturity

Advanced lines underpin stable quality. A qualified PCBA factory should have:

Fully automated SMT lines (supporting 01005, BGA, double-sided placement)

Wave soldering, selective soldering, and automated dispensing

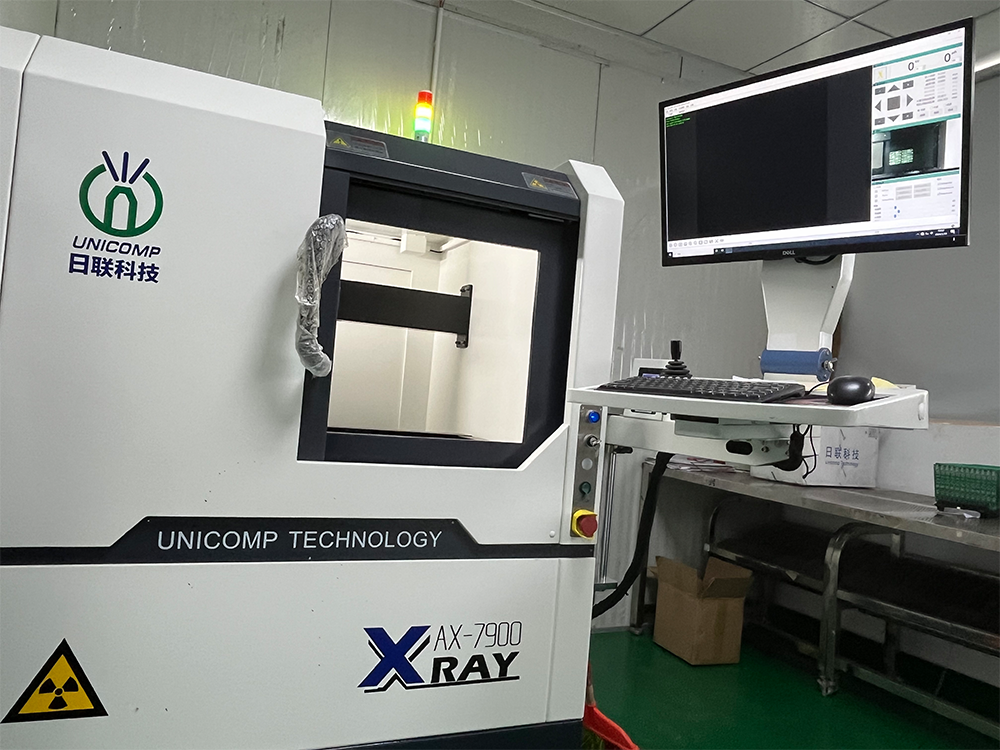

AOI and X-ray inspection systems

Lead-free reflow ovens with intelligent thermal profiling

Together these ensure high-precision assembly and consistent solder quality.

Process Control and Quality Consistency

Top manufacturers employ MES for full traceability and real-time capacity monitoring, so every lot can be traced to specific stations and materials.

Key checkpoints:

SMT and THT throughput

Process certifications (IPC-A-610 Class 2/3)

Automated inspection coverage (AOI/X-ray ratios)

Lot traceability and standardized production reporting

Step 3: Review Quality Assurance and Certifications

High-quality PCBA depends on standardized inspection systems and rigorous process control.

Common Certifications

ISO 9001: General quality management

ISO 13485: Medical electronics

IATF 16949: Automotive electronics

UL, RoHS, REACH: Safety and environmental compliance

Test and Inspection Flow

SPI solder paste inspection

AOI visual inspection

X-ray for hidden joints (BGA/QFN)

ICT in-circuit testing and FCT functional testing

Quality Tiers at a Glance

| Item | Top-Tier Manufacturer | Standard Plant | Low-Cost Subcontractor |

|---|---|---|---|

| Certification System | Comprehensive ISO/IATF/IPC | Partial certifications | No formal system |

| Inspection Coverage | AOI + X-ray + ICT | Mainly AOI | Visual checks only |

| Traceability | End-to-end QR code tracking | Manual records | None |

| Yield Rate | > 99.5% | ~97% | Unstable |

Step 4: Assess Component Sourcing and Supply Chain Strength

Authorized Channels

Prefer PCBA suppliers with access to authorized distribution (e.g., Digi-Key, Mouser, Avnet) to ensure authenticity and inventory stability.

Anti-Counterfeit and Incoming Inspection

Mature factories typically implement:

AVL (Approved Vendor List) control

AQL sampling with lot reports

Barcode systems for traceability

Alternatives and Risk Mitigation

In tight markets, a capable partner proactively proposes equivalent alternatives and proceeds only after your approval, preventing schedule slips that delay market entry.

Step 5: Evaluate Engineering Support and DFM Services

DFM Review

Experienced engineers will recommend design optimizations such as:

Pad size and spacing refinement

Silkscreen clearances to avoid pad coverage

Thermal balance and component heat-zone layout

These steps significantly reduce rework rates and solder defects.

Communication and Responsiveness

Choose teams offering bilingual engineering support and responses within 24 hours to shorten issue-resolution cycles.

Rapid Prototyping

Strong engineering is reflected in quick-turn capability. Leading factories with dedicated prototype lines can deliver samples in 3–5 days.

Step 6: Verify Lead Time, Flexibility, and Ramp-Up Capacity

Capacity and Ramp Experience

Ensure the factory can scale smoothly from small batches to mass production to avoid delays or supplier switches that compromise consistency.

Schedule Transparency

Look for visible production plans, ERP updates, and exception alerts so you can track progress in real time.

Flexibility

The ability to handle engineering changes or urgent top-ups quickly is a core indicator of partnership resilience.

Step 7: Check Cost Transparency and Total Value

Do not judge by unit price alone. Focus on total cost of ownership (TCO):

Quotes should include PCB fabrication, component sourcing, assembly, testing, packaging, and logistics

Confirm any fixture, NRE, or expedite fees

Compare vendors using a standardized quotation template to evaluate true value

Step 8: Confirm Data Security and IP Protection

NDA Coverage

Sign a comprehensive NDA covering Gerbers, BOMs, firmware, and proprietary design files.

Information and Facility Security

Facilities with access control, segregated internal networks, and periodic security audits better protect confidentiality.

Step 9: Verify Reputation and Customer References

Review key end-markets served (automotive, industrial control, communications, medical devices)

Request recent case studies or references

Conduct online or on-site audits to validate real process capability

Final Checklist

Technical and production requirements confirmed

Equipment and certifications verified

Quality and inspection systems validated

Component sourcing and anti-counterfeit controls in place

Engineering support and DFM capability confirmed

Lead time visibility and ramp-up plan available

Transparent, comparable cost breakdown

NDA and security controls signed and implemented

Customer references checked and factory audited

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact us

to Begin your Bessiness