Table of Contents

近期文章

How to Ensure PCBA Quality Assurance

In modern electronics, boards keep getting smaller while performance expectations soar. PCBA quality assurance therefore spans the entire product life‑cycle—from concept, design verification and sourcing to mass production, test, shipping and field feedback. A robust system combines:

Rigorous front‑end design rules

Controlled supply chain and material traceability

Standardised, data‑driven manufacturing and inspection

Continuous improvement based on failure analysis and statistical process control (SPC)

When each link is sound, you ensure PCBA quality that is reliable, cost‑effective and compliant.

1.Design Review and Verification

1.1 DFM & DFA Optimisation

Applying Design for Manufacturability (DFM) in PCBA and Design for Assembly (DFA) early prevents costly rework later. Check:

Clearances & paste windows match stencil/printing capability.

Trace width, spacing and via choices meet signal‑integrity and fabrication tolerances.

High‑speed impedance zones are routed and referenced correctly to curb reflections and crosstalk.

For DFA, avoid placing parts near board edges or connectors, and mark polarity clearly to reduce reverse installation.

1.2 BOM‑Gerber Consistency

Verify that every line item, reference designator and layer stack in the Gerber set matches the latest BOM revision. Automated lint tools catch orphan pads, broken nets and outline mismatches before release.

1.3 Early Prototype & Risk Validation

Combine ERC, SI/EMC simulation, and small‑batch prototypes to expose manufacturability or material‑fit issues long before volume build.

2 Component Selection & Procurement Control

2.1 Authorised Sources Only

Source active devices from OEMs or franchised distributors to avoid counterfeits. Audit suppliers for ISO 9001 accreditation, delivery history and transparency.

2.2 Batch‑Level Traceability

Every reel is labelled with lot code, date, and certificates (RoHS, REACH, MSDS). Linking these IDs to the work order enables rapid containment if a defect surfaces.

2.3 Incoming Quality Control (IQC)

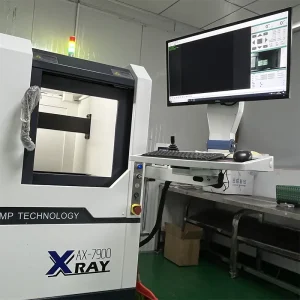

IQC inspects form, fit and function. High‑value ICs may undergo X‑ray fluorescence or third‑party lab verification.

3 Process Control During Assembly

3.1 Standardised Work Instructions

Line operators follow IPC‑A‑610 class criteria for acceptability and company‑specific SOPs. Certification and periodic re‑qualification keep skills current.

3.2 SMT & Hand‑Assembly Controls

Calibrated placement equipment, well‑designed stencils and controlled paste viscosity prevent offset and tombstoning. Ergonomic jigs and pictorial guides minimise hand‑insert errors.

3.3 Reflow & Wave Solder Profiles

Tailor soak, peak and cooling ramps to alloy, board stack‑up and component mass. The right curve stops cold joints, bridging and solder‑ball spatter.

3.4 Real‑Time Monitoring

SPI tracks paste volume; AOI flags rotation or bridging; oven profilers log each lot’s thermal curve. Data funnel into an SPC dashboard that triggers alarms for drift.

4 Inspection & Test Technologies

| Stage | Purpose | Typical Coverage |

|---|---|---|

| AOI | Fast visual screening of placement, polarity, solder bridges, voids | “First Article” & 100 % in volume |

| AXI | Hidden joint integrity for BGA/QFN/PoP | Void, head‑in‑pillow, insufficient solder |

| ICT | Electrical verification at node level | Opens/shorts, passive values, polarity |

| FCT | Functional simulation under power | Firmware, interfaces, sensors, load response |

| Environmental & Reliability | Temp‑cycle, vibration, salt‑spray, HALT | Automotive, aerospace, medical |

5 Material Storage & Handling

FIFO discipline for limited‑shelf‑life items like paste and adhesives.

Moisture‑sensitive devices stored per JEDEC J‑STD‑033 floor‑life limits and MSL bake rules

Full ESD program: grounded benches, ionisers, conductive packaging.

6 Continuous Improvement

Failure Analysis (FA) – cross‑section, SEM, EDS pinpoint true root cause.

Data‑Driven SPC – control charts flag drifts in placement accuracy, paste height, reflow soak.

Change Management – any material, process or software update undergoes engineering evaluation, pilot run and operator retraining before release.

7 Documentation, Training & Traceability

Visual SOPs with good/defect photos keep interpretation uniform.

IPC‑A‑610, J‑STD‑001 and ESD certifications raise workforce competence.

Unique barcodes on every board link operator ID, material lots and live process parameters in MES/ERP. Instant recall becomes a query—not detective work.

8 Tailoring Quality to End‑Use Markets

| Segment | Must‑Have Quality Focus |

|---|---|

| Consumer Electronics | Cosmetic consistency, fast turn, cost control |

| Automotive Electronics | Full PPAP/APQP files, 100 % functional & environmental test, long‑term traceability |

| Medical Devices | ISO 13485, controlled environment, complete life‑cycle risk management, regulatory audits |

Conclusion

Building PCBA quality assurance into every phase—from DFM review to final function test and SPC analytics—is the only sustainable way to ensure PCBA quality in an era of dense, high‑reliability electronics. Follow recognised IPC‑A‑610 standards, respect J‑STD‑033 storage rules, maintain rigorous ICT for PCBA, and close the loop with data. The payoff is fewer field failures, happier customers, and a reputation for uncompromising PCBA quality control.

Barry Ding

CEO

About us

We are PCBAYCT Electronics — your trusted partner in high-quality PCB & PCBA manufacturing, backed by 15+ years of expertise and industry-leading capabilities.

Contact Us

to Begin Your Bessiness