描述

Welcome to PCBAYCT, a trusted leader specializing in high-quality PCB Assembly (PCBA) solutions tailored to meet diverse industry requirements worldwide. Our extensive experience, advanced technology, and commitment to excellence enable us to deliver exceptional PCBA products to clients across North America, Europe, Asia-Pacific, and other global regions.

Global Collaboration and Reach

Our PCBA services extend globally, serving renowned enterprises in regions including:

North America (USA, Canada)

Europe (Germany, UK, France, Netherlands, Sweden)

Asia-Pacific (Singapore, Japan, South Korea, Australia)

Our broad regional partnerships underscore our ability to consistently meet international standards, ensuring reliability and top-notch quality.

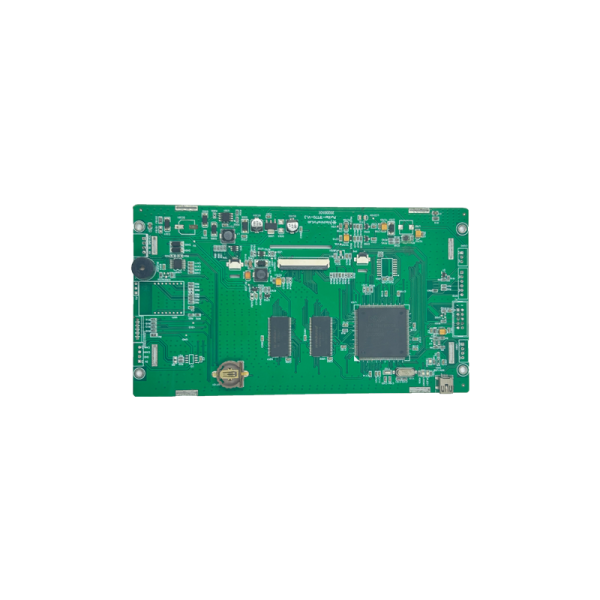

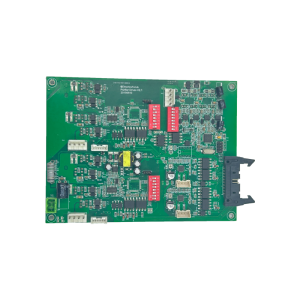

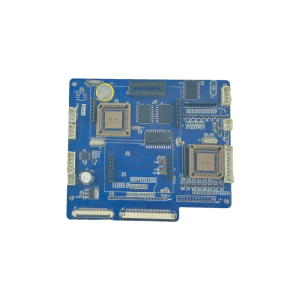

Diverse Range of Assembled Products

At PCBAYCT, our assembled products cover various sectors, including:

Consumer Electronics (smart home devices, wearables)

Industrial Control Systems (automation equipment, IoT solutions)

Automotive Electronics (vehicle sensors, GPS modules)

Medical Devices (diagnostic equipment, medical wearables)

Telecommunication Equipment (routers, modems, wireless devices)

Each product undergoes rigorous quality assurance processes to meet stringent industry-specific standards.

Tailored PCB Assembly Customization Process

Our PCB assembly customization is a structured and transparent process designed to meet your specific product needs:

Consultation and Requirements Analysis Detailed discussions to understand your unique project specifications and technical requirements.

Design and Engineering Support Expert assistance in PCB layout optimization, material selection, and design validation.

Prototyping and Testing Rapid prototype assembly to evaluate design feasibility and performance verification.

Mass Production Scalable production capabilities ensuring consistent quality and timely delivery.

Quality Assurance and Compliance Thorough inspections using advanced testing methodologies such as AOI (Automated Optical Inspection), X-ray inspection, and functional testing.

Logistics and After-sales Support Efficient logistics management and comprehensive after-sales services to guarantee long-term satisfaction.

SMT & PCBA Capability

| Material Type | Item | Min | Max |

| PCB | Dimension(length,width,height.mm) | 50500.5 | 5104604.0 |

| Weight | 2.0KG | ||

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,FPC | ||

| Surface finish | HAL,OSP,Immersion gold,Flash Gold,Gold Finger | ||

| Components | Chip & IC | 01005(0.25* 0.12) | 24*24 |

| Special size(Connector) | 1.6*0.8 | 100mm | |

| BGA Pitch | 0.3mm | 1.0mm | |

| QFP Pitch | 0.3mm | 1.0mm | |

| Components Type | Speed(CPH) | Accuracy(mm) | Camera |

| 01005**Chip** | 50K | 0.04 | |

| 1608Chip | 50K | 0.04 | Fix Camera |

| 1005Chip | 50K | 0.04 | Fix Camera |

| SOP16 | 20K | 0.04 | Fix Camera |

| QFP100 | 8K | 0.03 | Fix Camera |

| QFP256 | 8K | 0.03 | Fix Camera |

| BGA | 8K | 0.03 | Fix Camera |

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMD+connector | 5~200 | 6WD | 3WD |

| SMD+connector | 201~2000 | 7WD | 7WD |

| SMD+connector | ≥ 2000 | 7 ~ 9 WD | 8 WD |

| SMD+DIP | 5~200 | 5 WD | 4WD |

| SMD+DIP | 201~2000 | 7WD | 5 WD |

| SMD+DIP | ≥ 2000 | 8WD | 6 WD |

Remark: The above lead time is just for assembly time.

Comprehensive PCB Assembly Services Offered

Our factory is equipped to handle diverse assembly requirements, providing:

Surface-Mount Technology (SMT): Precise assembly of compact, high-density PCBs.

Through-Hole Assembly (THT): Robust solutions for applications requiring enhanced mechanical strength.

Mixed Assembly: Combining SMT and THT to meet complex product requirements.

Turnkey Assembly: Complete solutions covering component sourcing, PCB fabrication, assembly, and testing.

Box Build Assembly: Complete product assembly including enclosure fitting, wiring, and functional integration.

Why Choose PCBAYCT?

Expertise and Experience: Decades of industry experience with a highly skilled engineering team.

Advanced Facilities: State-of-the-art production equipment ensuring precision and efficiency.

Quality Commitment: Strict adherence to international quality standards including ISO 9001, ISO 13485, IPC-A-610, and more.

Responsive Customer Service: Dedicated customer support ensuring effective communication throughout your project’s lifecycle.

At PCBAYCT, we are dedicated to delivering innovative and reliable PCB assembly solutions tailored specifically to your business needs.